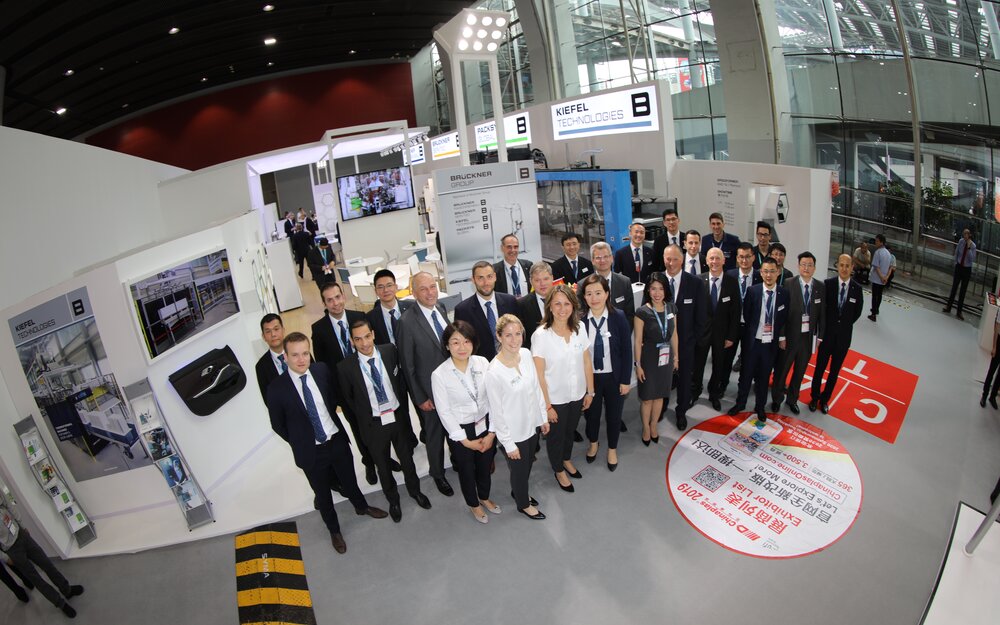

Chinaplas 2019: Speedformer KMD 78.1 Premium live presentations - magnet for visitors

27 May 2019

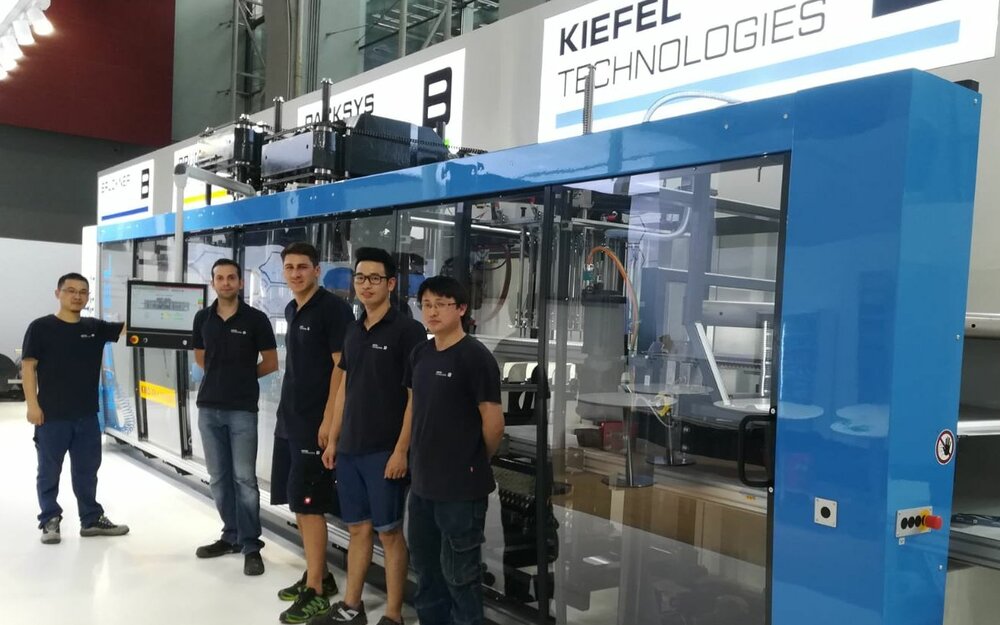

At the Chinaplas in Guangzhou, the Speedformer KMD 78.1 Premium compressed air forming machine impressed attendees.

The KMD 78.1 is the logical continuation of a success story built around the products of Kiefel's customers. At the booth, the KMD 78.1 demonstrated the production of Polypropylene takeaway trays made with a 12-cavity mold. A sealable thermoformed lid that can also be produced on a KMD completes the tray to provide a cost-effective and safe container for take-away soups or other liquid takeaway food. This is ideal for Asian markets, where consumers like to take their food from restaurants or mobile food stalls.

Kiefel's know-how has been incorporated into product development and design, as well as into the development and construction of tools. One of the achievements was optimal material distribution and perfect stackability. Both are the basis for the excellent quality of the molded parts.

The KMD SPEEDFORMER series of compressed air forming machines are in constant use worldwide in the packaging industry. Continuous innovation, maximum flexibility and well thought-out, stable and user-friendly mechanical engineering are winning features of this highly successful series. Perfect for the economic production of trays, hinged packaging or sorting inserts.

Cup forming – Everything from a single source

The KTR SPEED series machines offer the highest quality and maximum output for cup forming. Whether mass production on the KTR 6.1 SPEED or medium batches with the KTR 4 SPEED and KTR 5.1 SPEED.

Kiefel Packaging's Applied Polymer Research Center in Sprang Capelle / NL provides a sophisticated service concept. The services encompass everything from product development, prototyping, sample production and production optimization to a permanent service presence at customers' production facilities.

And there is more to come: the system concepts matched with high-quality tools as well as suitable stacking devices and automation modules, for the production of drinking cups, yoghurt pots, coffee capsules and plant pots, impressively underscored Kiefel's industry leadership at the exhibition.

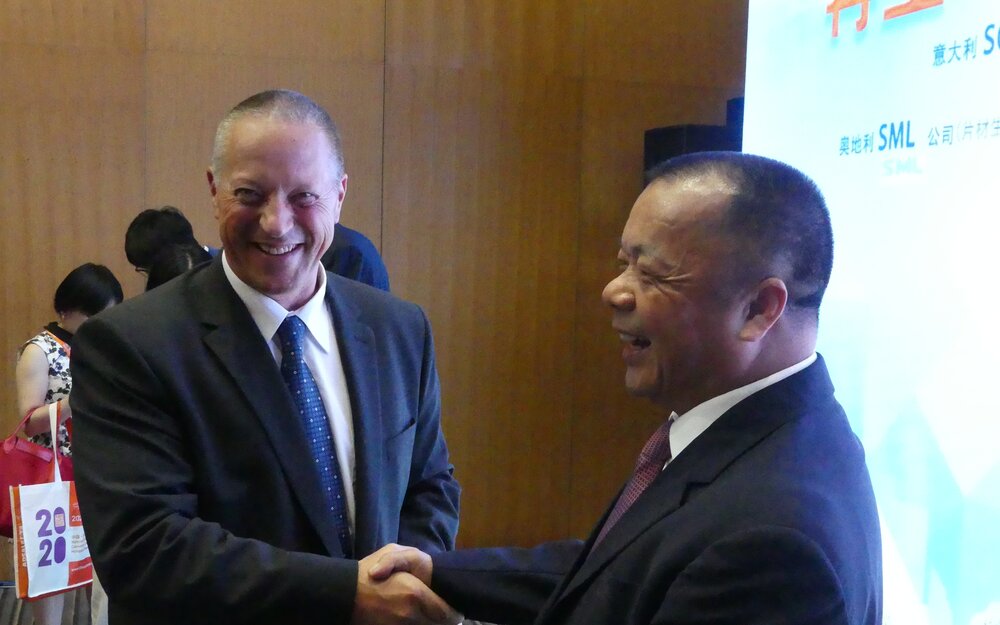

Circular Economy – Contract signing with Wuzhou Guolong

Guolong is one of the first Chinese companies significantly invest in the Circular Economy. Guolong has chosen proven technology partners for the implementation of the PET recycling project.

In addition to the recycling specialists SOREMA, EREMA, SML and Tomra, 6 thermoforming systems from Kiefel have also been included. Five KMD Smartformers and a KTR 6.1 Speed are complete the cycle and will produce Guolong trays and cups made from recycled PET.

During the Chinaplas 2019, the supply contracts were festively signed by Mr. Guo, the owner of the Guolong Group and the managing directors of the companies involved.

For Guolong this represents the first step into a sector undergoing strong growth. In china, Circular Economy has become a major topic; extensive government decisions are forcing its implementation.

This year's Chinaplas thereby surpassed all expectations and was very satisfactory and highly positive for Kiefel.