Sustainable packaging solutions from natural fibers

We put your product first and rethink product design and functionality, material and composition towards a more sustainable product. Depending on that we adapt the manufacturing process and optimize machines and tools for your production. Your sustainable product can be recycled easier and together we are closing the loop.

You choose whether you want to use classic recyclable plastics like rPET, bio-based materials like PLA or even natural fibers.

End consumers demand sustainable and green packaging. Kiefel offers the right machine solutions for this - thermoforming with natural fibers - Kiefel Fiber Thermoforming. With our NATUREFORMER KFT 90 you can produce your sustainable packaging product from natural fibers.

Benefits of Fiber-based Packaging

Optimal product protection

Sustainable packaging solutions

Refinement

Customized product design

From Waste Paper to New Fiber Formed Packaging

Kiefel technologies and solutions make it possible

Paper and cardboard – dissolved in a water bath – create the raw material, known as pulp. Through application of pressure most of the water is removed and the wet basic form is created.

In the next step, the remaining moisture is removed and the basic form is dried by applying high pressure and temperature. The combination of the applied heat and pressure results in a very robust material for high-quality and dimensional stable packaging.

Alternatively, virgin fibers (unprocessed cellulose) can be used to comply with the regulations in the food industry for packaging solutions made from paper.

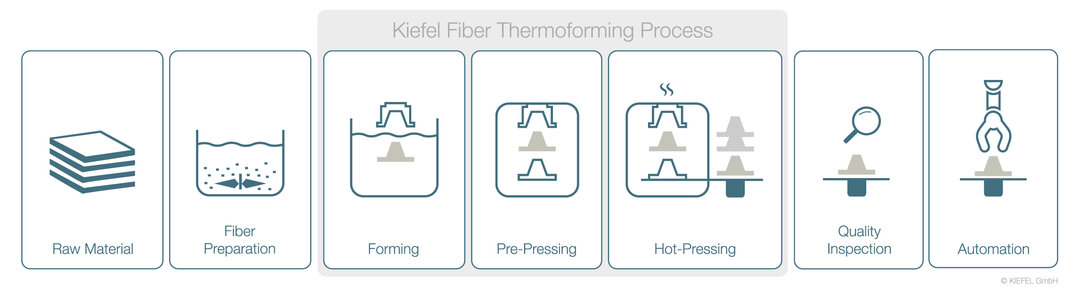

The Kiefel process

- Raw Material: primary or secondary fibers

- Fiber Preparation: refining with water to lower fiber concentration

- Forming: the majority of the water is extracted from the fiber mixture through the forming tool via negative pressure

- Pre-Pressing: continuous extraction of water, preformed product is pre-pressed and further drained with elastic tool

- Hot-Pressing: reduction of residual moisture to a minimum through pressure and heat, refinement of contours/engravings, handover to lifting conveyors

- Quality inspection e.g. camera inspection systems (add-on)

- Automation solutions e.g. sleeving, boxing (add-on)