Innovative packaging solutions at Chinaplas 2021

01 mrt 2021

In addition to the proven steel rule cutting machine SPEEDFORMER KMD 78 (premiere at Chinaplas!) the company will also demonstrate its extensive materials expertise for a wide range of applications for the circular economy at Hall 10, Booth 10P23 from April 13 - 16, 2021

The requirements of packaging manufacturers worldwide have increased. In addition to established plastics, machines for processing recycled or bio-based materials as well as natural fibers are also becoming increasingly important. Kiefel, a Germany-based, globally active market leader in high performance thermoforming machines and turnkey solutions, is presenting solutions for this demand at Chinaplas. In addition to the proven steel rule cutting machine SPEEDFORMER KMD 78, which will be shown live there for the first time, the company will also demonstrate its extensive materials expertise for a wide range of applications for the circular economy at Hall 10, Booth 10P23.

Live demonstration of SPEEDFORMER KMD 78

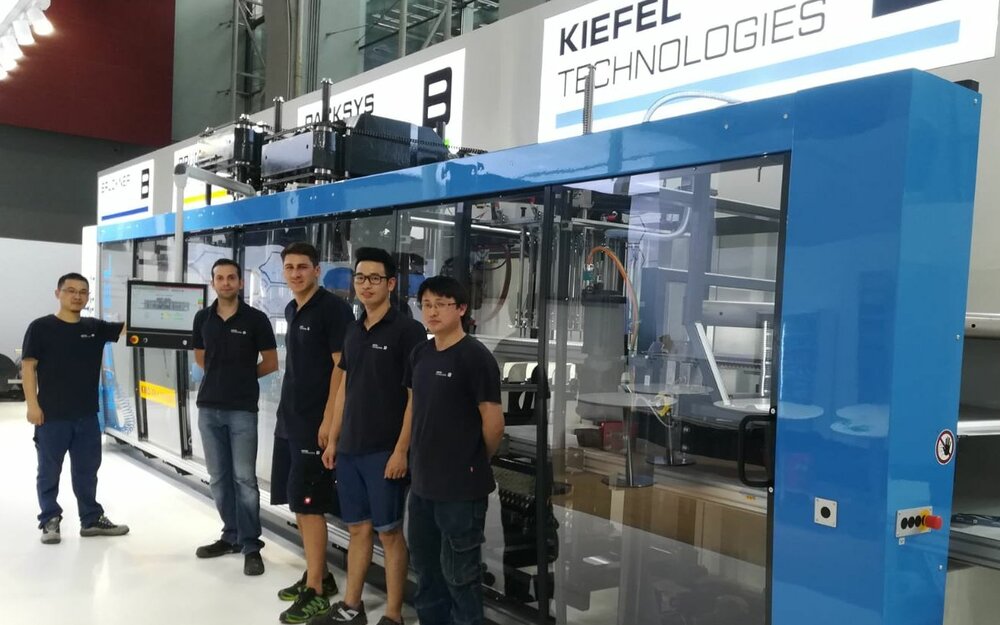

For the very first time, Chinaplas visitors will experience the advanced design of the Kiefel SPEEDFORMER KMD 78 in a live demonstration.

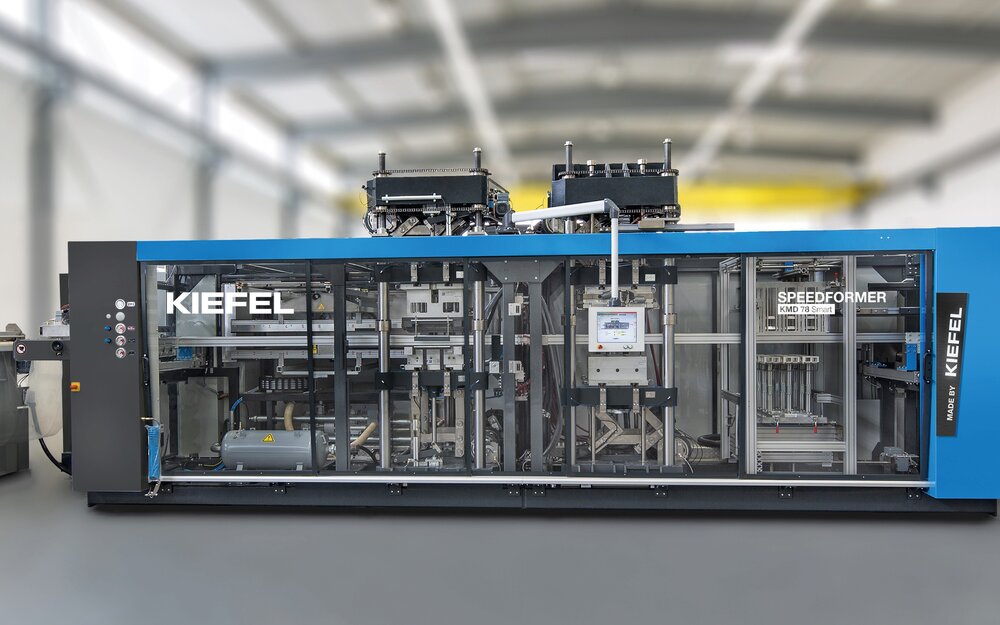

The SPEEDFORMER KMD 78 is used for the manufacture of food and non-food plastics packaging using various materials such as PET, PP,PS,PLA,PE or recycled plastics. It offers maximum output and efficiency in mass production and is economical even for small quantities.

The KMD 78 is a standard machine, made to increase profit and reduce production costs for example through accurate servo-driven tables, fast and easy tool change and proven HMI for operation and maintenance. The forming station with 3rd motion servo-plug-drive guarantees optimal material distribution. As stacking is the first step into automation, the platform also offers three different stacking solutions. The unique Kiefel “Kiss cut” technology ensures reliable stacking, extended knife service life and therefore minimized labour costs.

Expanded materials competence for a circular economy

The need for circular economy solutions for plastic packaging requires the industry to follow a holistic concept starting from design, following the entire life cycle. This is why Kiefel applies the Rethinking Approach, which involves helping to shape customer projects as a partner from the outset so that the most sustainable, innovative solution is realized – based on the customer´s needs. Therefore the company not only develops, designs, manufactures and supplies machines, tools and automation for the processing of polymer-based materials, but also for bio-based and fiber-based material.

At Chinaplas, Kiefel will highlight extensive experience values worldwide:

- China: Enabling a closed cycle for food packaging made from PET.

- USA/Canada: Successful transition to more recyclable end products, e.g. from PS to PP.

- Europe: Recyclable reuse through production of PET bowls in the respective recycling colors.

In addition, Kiefel will provide insights into results from various research initiatives in which the company is involved, including:

- Holy Grail: Material research to support better Circular Economy e.g. for improved waste sorting through digital watermarks

- PrintCyc initiative: Remarkable results for the recycling of printed plastic film and processing of recycle.

Solutions for the appliance industry

Kiefel is a key partner for high-quality refrigerator components, a manufacturer of thermoforming machines for the flexible production of HIPS and ABS refrigerator inner-liners and door-liners, with multiple colours of one material handled by a single machine. Chinaplas attendees can also learn more about the latest developments in economical production for almost all styles of refrigerators, whether French Door, Side by Side, Top- or Bottom Freezer, Freezerless, Compact or Wine refrigerators. Both simple and complex shapes can be efficiently produced with a KID Series SHARPFORMER Vacuum-Pressure former, with output reaching 150 pcs/hour. The new industry milestone for high-speed and energy-efficient production of door-liners, formed and trimmed in a single cycle will also be presented. The compact High-pressure KID-BFS door-liner with outstanding output up to 300 production cycles/hour, which has already been discovered and tested by some of the most renowned manufacturers in the Appliance Industry in Europe, is now on the way to China.

The Kiefel team looks forward to welcoming visitors at Hall 10, Booth 10P23.

https://www.chinaplasonline.com/SuppliersDB21/productinfo/eng/product_info?compid=268021&SeqId=1