Kiefel Driving Sustainability

Sustainability at Kiefel

Tremendous changes like climate change and environmental pollution are impacting our society. As a thermoforming and joining technology company, we take responsibility for a sustainable future while boosting efficiency for us and our customers.

The four key dimensions of our sustainability:

- Company: Future-oriented management, sustainable growth, zero tolerance for corruption.

- Products: Resource-saving concepts, recyclable materials, digital solutions.

- People: Healthy working conditions, education and training, equality, regional engagement.

- Environment: Reduced resource consumption, recycling of valuable resources and waste.

Future-orientated and transparent corporate management

Our permanent striving for future-oriented acting in all our activities is among the most important ingredients for being the leading solution provider for the development and implementation of the most sustainable technology.

EcoVadis

The world's largest provider of sustainability ratings, EcoVadis, has awarded the company, consisting of the Freilassing-based Kiefel GmbH with subsidiaries in Micheldorf (Austria) and Sprang-Capelle (Netherlands), a silver medal in the overall ranking. This places Kiefel among the most sustainable 15% of all companies audited by EcoVadis and even among the top 4% of the industry.

The EcoVadis certification is based on an extensive questionnaire on the four categories of "Environment", "Labor and human rights", "Ethics" and "Sustainable procurement". Since the last assessment in 2023, the overall score has improved thanks to the implementation of additional policies and measures. According to the provider, they already certify more than 130,000 companies in over 180 countries in a wide variety of industries worldwide.

Initiative Blue Competence

We are Alliance Member of the Sustainability Initiative Blue Competence. Blue Competence is an initiative of the VDMA for promoting and communication of sustainable solutions for the Mechanical Engineering Industry. By using the trademark “Blue Competence”, we commit ourselves to these twelve Sustainability Guidelines of the Mechanical Engineering Industry.

Zero Tolerance for bribery and corruption

Trust is the cornerstone of our business: Compliance, responsibility, and ethical behavior define our values.

Our commitments are guided by our Code of Conduct, the core of our corporate culture and a reflection of our ethical responsibilities

Resource-saving machine and product concept

Sustainability guides our path when it comes to innovation. We rethink product design and functionality, materials and composition with a view to a more sustainable product. Correspondingly, we adapt manufacturing processes and optimize machines and tools for production.

You can choose to use classic, recyclable plastics such as rPET, bio-based materials such as PLA or natural fibers – Kiefel has the machine solution. Your sustainable product can thus more easily be recycled and returned to the circular economy, be biodegradable or even compostable.

In addition, we have determined the Product Carbon Footprints (PCF) for our machines and reference customer products in accordance with the DIN ISO 14067 and GHG Protocol Product Standard. The PCF is subject to an annual review process.

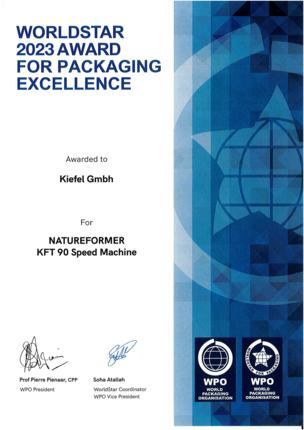

NATUREFORMER KFT 90 receives Gold Award at the German Packaging Award 2023

NATUREFORMER KFT 90 as Advanced Version receives Gold Award in the German Packaging Award 2023 in the Packaging Machines Category.

Our KFT 90 as Advanced Version, which allows customers to reduce cycle times by up to 30% in fiber-packaging production, was further honored with the Gold Award for particularly groundbreaking innovation among the winners.

Customer Innovation & Material R&D Center

Research & Development for more sustainable machines & end products

At our Customer Innovation and Material R&D Centers we advance our research activities into more sustainable technologies, processes and materials.

Our customers benefit here from sample productions and machine demonstrations that are optimally tailored to individual requirements.

>> Customer Innovation Center Fiber Packaging

Digital Products

Digitalization is continuously making processes more efficient and, most importantly, more sustainable.

For machinery and equipment, the Group companies rely on intuitive human machine interfaces (HMI), enabling, among other things, resource-efficient control of the various processes as well as decentralised maintenance. We received the red dot award design in 2020 for the design of our HMI.

After sales services are also performed remotely. Not only do they help you reduce time and save travel costs, but also prevent C02 emissions.

Human rights and corporate due diligence

We take an active role for a better future and are committed to contributing to a healthy environment and a society worth living in through sustainable action. We want to achieve our economic success only in accordance with internationally recognized human rights standards and laws.

In this context, we have committed ourselves to the ten principles of the UN Global Compact and we support the 17 global Sustainable Development Goals (SDGs) of the 2030 Agenda.

Ensuring healthy working conditions

The people who work together at Kiefel are the cornerstone of our success.

Therefore, we do everything for a healthy working environment, from state-of-the-art work clothes and shoes, to related accident prevention equipment (such as eye protection glasses, ear plugs, gloves, etc.). In addition, annual occupational safety training, adapted to different job profiles, is mandatory for all employees.

In addition, we cooperate with appointed company doctors at many sites and an occupational safety specialists. The company doctor carries out occupational medical check-ups for employees and advises on all medical issues associated with work, the workplace, and occupational medical precautionary measures.

The occupational safety specialist works closely with the company doctors to provide advice and support for accident prevention and in identifying potential accident risks. Responsibility for work safety in the company lies with the occupational safety officer, the safety specialists, and the management.

Furthermore, employee benefits including discounts for local recreational facilities are offered by Kiefel.

High quality education and training

#Kiefeleducates

Exchange and education are key to sustainability. Through school presentations and university excursions, we share expertise on materials like plastics and natural fibers and showcase future technologies. We also gain valuable feedback and explore solutions, such as research collaborations.

FH Salzburg Visit | Students of the "Circular Economy" module toured our facilities, learning about our commitment to a functioning circular economy and fiber thermoforming.

Elementary School Lecture | Teaching young students about the circular economy—from production to recycling—demonstrates the broad application of plastics and fiber products.

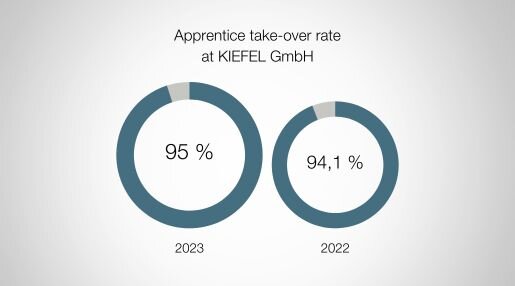

Kiefel supports employees’ professional and personal development, often from apprenticeship onward. Over 95% of last year’s apprentices stayed with us.

Our motto: "Potential needs opportunity to become effective." The Kiefel Apprentice Academy helps young people transition from school to work by fostering social, personal, and technical skills.

Excellent Training Organisation

Successful young talents - as a recognized IHK (Chamber of Industry and Commerce) training company and for the strong performance of our trainees, we have repeatedly received the IHK award. The seal stands for quality and excellence in training.

Furthermore, Kiefel offers internships for school pupils and university students. This gives them exciting insights, practical experience and opportunities to pursuing their careers at Kiefel.

Our commitment for young people also includes our participation at the MINT initiative and Girls’ Day. The aim is to introduce them to technical professions, in particular, and get them excited about STEM professions (i.e. professions related to Science, Technology, Engineering and Mathematics).

Equality and reduction of inequalities

At Kiefel there is no room for discrimination.

Our commitment in our Code of Conduct is part of daily business for us: Nobody is discriminated because of ethnic origin, gender, religion or beliefs, disability status, age, sexual identity or any other factors.

We are proud that employees of 28 different nationalities form our Kiefel Team, creating an atmosphere of diversity, tolerance, and equal opportunity.

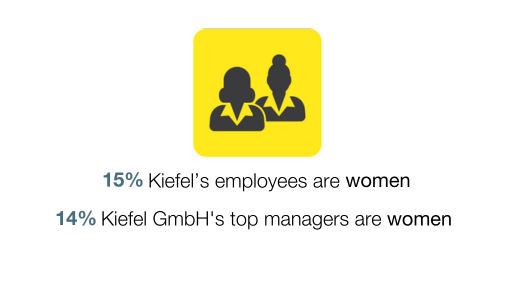

Around 15% of Kiefel employees are women and they make up 14% of the top management at Kiefel GmbH.

Our salary structure ensures fair and equal pay, that is determined by the position, qualification and experience. We take care to ensure that working hours do not exceed the maximum permitted under the applicable laws and regulations.

Our representative for severely disabled employees provides assistance with applications and correspondence as well as providing support options at the workplace.

And of course, we take a stand for equality and reduce inequalities as to the greatest possible extent.

Regional commitment and social engagement

As an internationally active group, Kiefel has a social responsibility that extends beyond its own employees.

Sponsorship and donations form a significant part of this social engagement. All corporate units and a large number of employees support regional clubs, cultural initiatives and organizations through donations and volunteer work.

Projects of the heart - Supporting what is close to the heart

Thanks to a newly introduced opportunity for employees to get their project sponsored by Kiefel, they were able to suggest charitable projects or non-profit organizations that are close to their hearts and to which they themselves are committed. The management then drew lots for this year's three "projects of the heart" from all the submissions.

Buy Food with Plastic

This organization allows locals in India, Nicaragua, and Ghana to "pay" for hot meals with plastic bottles. The collected bottles are recycled into new products.

ASASE Foundation

Women in Accra, Ghana, collect plastic waste, recycle it into regranulate, and sell it to recyclers. This material is used to create sustainable products like paving stones and roof tiles. The project also provides fair jobs, ensuring women and their families a stable income. Supported by Brückner Group.

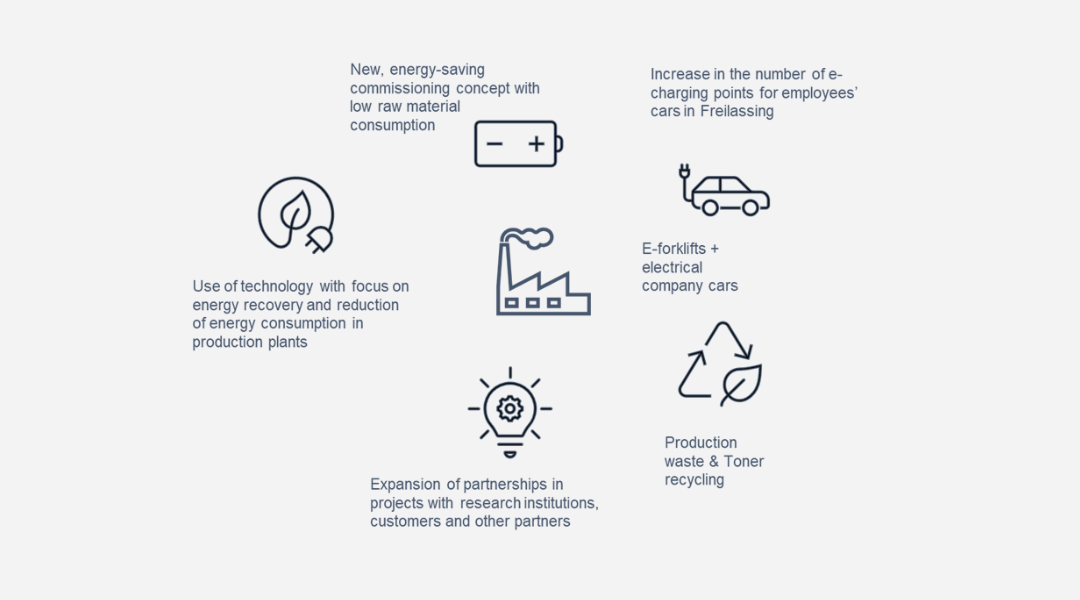

Reduction of resource consumption

Kiefel actively reduces resource consumption and continuously optimizes energy performance. Our machines are primarily made of recyclable metals, while plastics and chemicals are used in minimal amounts. We also support biodiversity by planting native vegetation on our premises, creating habitats for insects and birds. Environmental aspects such as transport and energy consumption are analyzed throughout the entire product lifecycle to minimize ecological impact.

R&D initiatives & partnerships

NEXTLOOPP - Recycling of PP for food-grade applications

The NEXTLOOPP initiative focuses on closing the loop of mechanically recycled food-grade polypropylene. The mechanical recycling of PP waste into high-quality rPP is an important step towards creating a sustainable circular economy. The circular economy can only be fully realized if plastics can be recycled back into food-grade applications. As this is not yet possible for mechanically recycled PP today, there is still work to be done here. We are convinced that NEXTLOOPP will make a unique and valuable contribution to closing the loop on food-grade PP. As part of this initiative, tray-to-tray and cup-to-cup recycling will be given a real opportunity for market introduction. We are proud to be a member of this initiative.

PrintCYC - successful recycling of printed plastic films

The PrintCYC (Printed PP films for mechanical recycling) project group explored ways to create circular economy solutions. The specific target of the project was to understand the impact of different ink formulations on the mechanical PP and PE recycling process. Furthermore, the re-usability of PP and PE recyclates (rPP / rPE) made from printed post-industrial film waste was evaluated in cast film, blown film, compression moulding and thermoforming technologies as well as the biaxial stretching process.

Members of this project were Kiefel, Brückner Maschinenbau and PackSys Global, the film producer Profol, the ink manufacturers Huber Group and Siegwerk, the converters Constantia Flexibles and Wipak as well as the recycling specialist Erema.

Holy Grail - digital watermarks for better sorting

In order to improve the sorting and consequently the recyclability of plastics, renowned brand owners, such as Procter & Gamble, have initiated the European “HolyGrail” project, in which Kiefel participates.

This involves using digital watermarks on packaging to obtain more material information, e.g. whether a material used to be food-safe. The printed or imprinted watermarks (largely invisible QR codes) are scanned and provide information about the material composition. More detailed sorting ensures a higher quality of recyclates and thus makes it easier to achieve recycling targets.

Digital Product Passport with R-Cycle

Kiefel is now a member of the R-Cycle. An association of companies and organizations that are committed to the global standardization of digital product passports for plastic products - based on GS1 standards.

R-Cycle is the open traceability standard for sustainable plastic products and packaging. With the digital product passport, (recycling)-relevant information is automatically recorded during packaging production and filling, forwarded through the value chain and made retrievable via a corresponding marking (e.g. digital watermark). This enables waste sorting systems to identify recyclable packaging and form recycling-friendly, unmixed fractions. This is the basis for obtaining high-quality recyclates and a functioning circular economy.

Recycling of valuable resources and waste material

Thanks to environmental site management, Kiefel guarantees energy-efficient operations, reduced carbon emissions and careful use of resources while also protecting water and biodiversity on company premises.

Responsible waste management ensures that waste is treated like secondary raw materials, i.e. sorted by type and recycled appropriately.

Kiefel’s corporate carbon footprint was first calculated for the 2020 business year. Corporate environmental management also takes into account the supply chain and logistics.

Kiefel is guided by the state of the art in all environmental protection and environmental management measures.

Sustainability at Kiefel

We are a part of the Brückner Group

Brückner Group launched the company wide initiative "Yes, we care" in 2017. As a project that is as much an acknowledgement to our own responsibilities in the matter of plastics and sustainability, as it is a promise to the employees in all the Brückner Group companies.

Sustainability report and magazines

The sustainability report of the Brückner Group contains detailed information about the company, our projects and activities with regards to sustainability as well as the most current non-financial key performance indicators.

This second sustainability report of the Group is based on the GRI standards. Starting with fiscal year 2025 the Brückner Group is subject to the CSRD regulations of the EU. As a consequence, the next sustainability report will be part of the group management report.