请注意此信息只有英文版本

Plastindia 2012

05 Feb 2012

At Plastindia 2012 the members of the Brückner Group present highlights in efficiency and productivity for India’s plastics and packaging industry: (Hall 12, Booths 12D3).

KIEFEL: New technologies for increased economic efficiency

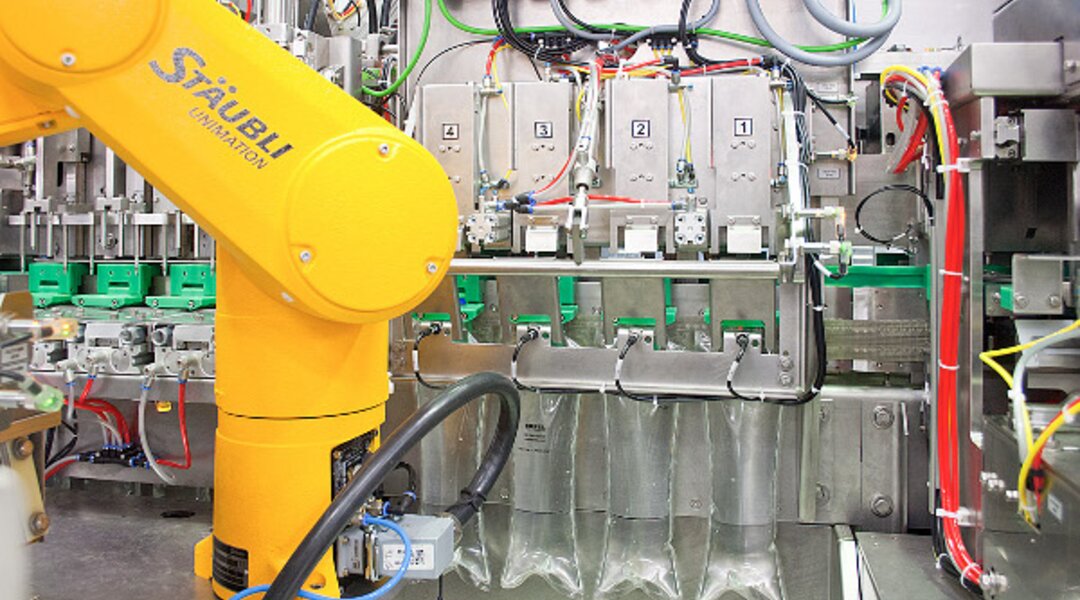

Medical Technology: Whether you are looking for thermo-contact or radio-frequency welding, flat or tubular film material, KIEFEL can provide manufacturing solutions for infusion bags that fulfil the highest performance specifications. Thanks to its newly-developed IV Express, welding-technology specialist KIEFEL meets the needs of the market to perfection. An innovative line for the production of IV bags with integrated filling Individual solutions for the Automotive Industry: KIEFEL is one of the international market leaders wherever the processing of plastics for the automotive industry is concerned.

Working in close cooperation with our customers, we plan and provide complete solutions for the production of interior trim components, like instrument panels, door panels, consoles and covering elements, map pockets, pillar liners, sun visors Appliance Industry: Technologies for efficient production of refrigerator inner and door liners Packaging Industry:High-performance pressure forming and cup forming machines

The SPEEDFORMER KMD Series set the standard for automatic pressure forming machines Tried-and-tested technology for the cost-efficient mass production of packaging items made of plastic: the KIEFEL SPEEDFORMER KMD Automatic Pressure Forming Machines.The Sophisticated machinery design, the innovative drive technology and the SIMOTION Control System of Siemens ensure faster and more precise movements of the SPEEDFORMER machines. Typical applications of the KMD SPEEDFORMER include trays and containers, hinged packaging, blister packs, tub lids and sorting elements.

Cup forming – time for SPEED and performance

Yogurt cups, drinking cups, cups for use with snap-on lids or plant-pots, KIEFEL’s Thermorunner KTR SPEED Cup Forming Machine combine intelligent technology, perfect quality and optimum production rates with low costs. Brückner Maschinenbau (booth 12D1): Brückner Maschinenbau (booth 12D1): Solutions for an efficient production of high performance plastics film For the manufacture of thin flexible BOPET packaging film Brückner presents a wide range of lines, comprising various working widths and outputs BOPET film for industrial and optical applications – Brückner offers innovative stretching technologies, providing film producers comparative advantages BOPP lines: Visitors of the Brückner booth will get a deeper insight in high quality solutions for all film types from plain to multi-layer, high clarity to opaque, barrier, shrink or metallizable for various applications Brückner presents line concepts and a full know-how package for the highly efficient production of high quality capacitor films High output CPP lines: Unmatched net film widths of 6.2 meters BOPA lines for modern first class applications Brückner Servtec (booth 12D1): Profitable and power-saving operation of existing lines PackSys Global (booth 12C2): For the first time in India - New heading machine for cosmetic tubes At Plastindia PackSys Global will be presenting for the first time in India its new LSH heading machine for cosmetic tubes. The LSH is a newly designed compression moulding heading machine which runs at speeds up to 80 tubes/minute. It is the newest machine in PSG's series of "quick change" machines catering to customers who need or want to be able to change the product being produced quickly and reliably

Medical Technology: Whether you are looking for thermo-contact or radio-frequency welding, flat or tubular film material, KIEFEL can provide manufacturing solutions for infusion bags that fulfil the highest performance specifications. Thanks to its newly-developed IV Express, welding-technology specialist KIEFEL meets the needs of the market to perfection. An innovative line for the production of IV bags with integrated filling Individual solutions for the Automotive Industry: KIEFEL is one of the international market leaders wherever the processing of plastics for the automotive industry is concerned.

Working in close cooperation with our customers, we plan and provide complete solutions for the production of interior trim components, like instrument panels, door panels, consoles and covering elements, map pockets, pillar liners, sun visors Appliance Industry: Technologies for efficient production of refrigerator inner and door liners Packaging Industry:High-performance pressure forming and cup forming machines

The SPEEDFORMER KMD Series set the standard for automatic pressure forming machines Tried-and-tested technology for the cost-efficient mass production of packaging items made of plastic: the KIEFEL SPEEDFORMER KMD Automatic Pressure Forming Machines.The Sophisticated machinery design, the innovative drive technology and the SIMOTION Control System of Siemens ensure faster and more precise movements of the SPEEDFORMER machines. Typical applications of the KMD SPEEDFORMER include trays and containers, hinged packaging, blister packs, tub lids and sorting elements.

Cup forming – time for SPEED and performance

Yogurt cups, drinking cups, cups for use with snap-on lids or plant-pots, KIEFEL’s Thermorunner KTR SPEED Cup Forming Machine combine intelligent technology, perfect quality and optimum production rates with low costs. Brückner Maschinenbau (booth 12D1): Brückner Maschinenbau (booth 12D1): Solutions for an efficient production of high performance plastics film For the manufacture of thin flexible BOPET packaging film Brückner presents a wide range of lines, comprising various working widths and outputs BOPET film for industrial and optical applications – Brückner offers innovative stretching technologies, providing film producers comparative advantages BOPP lines: Visitors of the Brückner booth will get a deeper insight in high quality solutions for all film types from plain to multi-layer, high clarity to opaque, barrier, shrink or metallizable for various applications Brückner presents line concepts and a full know-how package for the highly efficient production of high quality capacitor films High output CPP lines: Unmatched net film widths of 6.2 meters BOPA lines for modern first class applications Brückner Servtec (booth 12D1): Profitable and power-saving operation of existing lines PackSys Global (booth 12C2): For the first time in India - New heading machine for cosmetic tubes At Plastindia PackSys Global will be presenting for the first time in India its new LSH heading machine for cosmetic tubes. The LSH is a newly designed compression moulding heading machine which runs at speeds up to 80 tubes/minute. It is the newest machine in PSG's series of "quick change" machines catering to customers who need or want to be able to change the product being produced quickly and reliably