Always on the move – despite dialysis

28 Nov 2018

Visit to a dialysis centre, looking at everyday life for the hospital and patients.

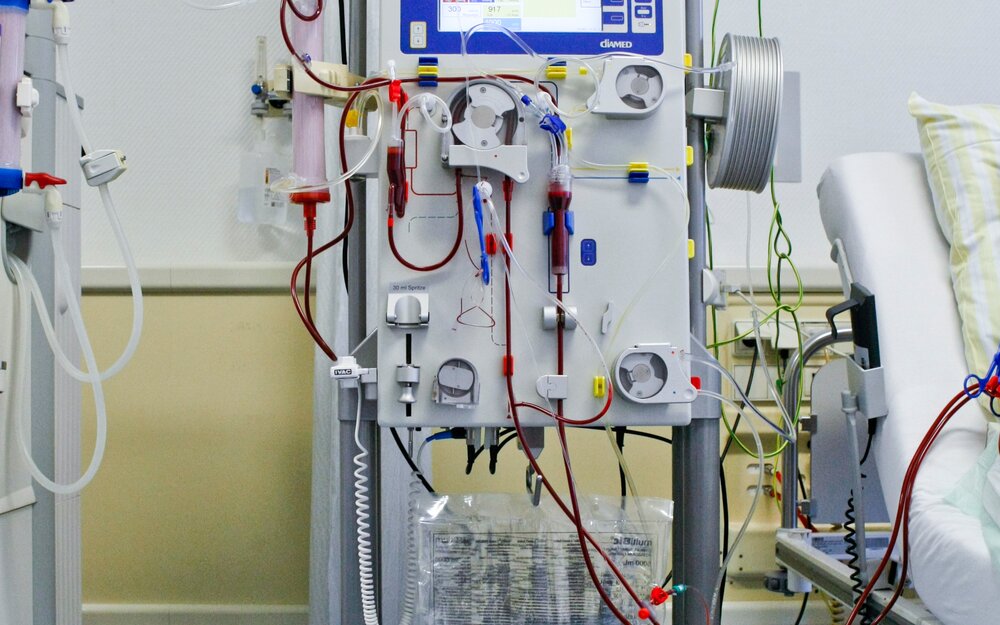

Dialysis centre of the Prosper Hospital in Recklinghausen, 9:00 am: Dialysis orderlies and specialist nurses connect dialysis patients to dialysis machines, check blood pressure, adjust the blood flow, and carry dialysis bags with electrolyte solutions to individual equipment. The clinic carries out 10,000 kidney replacement procedures per year using various dialysis procedures. One of the patients is Eckhard Freiling, who has been on dialysis for six years. He has his illness under control. Today is another dialysis day for him.

Most outpatients are connected to haemodialysis. The blood flows through thousands of small porous hollow fibre membranes, which are externally surrounded by an electrolyte solution and enclosed by a plastic capsule. Harmful substances up to a certain size diffuse from the blood through the membrane into the highly sterile electrolyte solution. Their salt concentration can be adjusted individually slightly below the salt concentrations in the blood of the patient. If there are insufficient haemodialysis places or if a patient is in intensive care, mobile haemofiltration devices are used. The blood in turn flows through the filter membrane, via which the pressure gradient now filters plasma fluid with harmful substances from the blood. Dr Joachim Kühne, chief physician of the nephrology department of the Prosper Hospital, explains: "Of course, we have to replace the fluid taken from the body. We therefore venously deliver a highly sterile solution of electrolytes from bags to the patient. The composition of salts such as sodium, potassium, calcium, bicarbonate and other elements is tailored to the needs of the patient."

Part of life

All 15 beds on the dialysis ward are occupied this morning - the usual everyday occurrence for doctors and caregivers. The patients listen to music, read, talk to each other and wait. The four to five hours that they spend here three times a week have also become part of their lives. Eckhard Freiling is in the Prosper every Monday and Thursday morning, having his blood detoxified and his body dehydrated. Today he is connected to hemofiltration. The apparatus pumps off nearly 350 ml of blood per hour and presses the plasma water with the toxins from his blood through the filter membrane.

Below the filter units, two bags are attached to a scale: one supplies it with healthy electrolyte solution, which replaces the plasma water that has been pressed out; the other takes the plasma water with the toxins. "The scales allow us to keep the fluid balance under control. We are replacing some of the liquid that the filtration system is removing from Mr. Freiling," explains Kühne. Because dialysis also serves to dehydrate the body. When the kidneys cease to function, patients can no longer excrete water and this accumulates in tissues, lungs and other organs. In this way, Freiling only gets back the amount of fluid he needs for his well-being via the electrolyte solution.

Illness must not dominate life

The 70-year-old retiree takes a relaxed look at the high-tech equipment by his bed. He has long since become accustomed to the situation because he has been dependent on dialysis for six years: "I had a jaw operation. Even before that, my kidney values were not so good. One week after the operation, I came to the hospital with acute symptoms of poisoning and was initially in the intensive care unit for three weeks. Afterwards, it was clear that my kidneys were not working properly anymore."

However, the optimist did not give up after this diagnosis. A specialist created a shunt - the necessary short-circuit connection between an artery and vein for dialysis – and Freiling accepted his situation. "Back in the hospital I swore that the disease would not restrict my life to the point that I could not think about anything else. So I started to engage constructively with it." The sprightly man attends lectures, conducts Internet research and is in touch with the waiting list office with Eurotransplant, the organ donation agency. One thing was quickly clear to him: A donor kidney would not only give him a lot of time and flexibility, but also increase his life expectancy. Pragmatically, Freiling points out: "A new kidney increases my life expectancy by five to ten years. That's why I signed up to Eurotransplant's European Senior Program. "This program also allows older people to donate their kidneys to older people. Freiling explains with satisfaction: "This program has reduced waiting times for us older people from eight to five to six years. Although I won't be able to visit many holiday destinations for a year after a transplant, I'll accept that."

On Journeys

The young-at-heart retiree and his wife don't let the disease spoilt their holidays. They regularly travel to Fuerteventura or to the North Sea; soon they will be holidaying in the Netherlands Antilles. The holiday preparations involve a few more steps than they used to. Freiling checks online to see which dialysis facilities are available near his holiday home and he contacts them in advance: "I send my doctor's reports there, which I have translated if necessary. Then I arrange the dialysis appointments in advance and it starts." The dialysis centre staff know him on Texel and Norderney, as well as on Fuerteventura. The costs are covered by the health insurance, from which Freiling always gets the guarantee of reimbursement in advance. Since joining Eurotransplant's list for organ donation, he has registered his upcoming vacations at the waiting list office because: "You never know when a donor organ will become available, therefore I must always be available for Eurotransplant. When the time comes I want to go under the knife without delay. During the holiday, I have my name listed as "not transplantable" at the waiting list office and they know that I'm not available for this period. "Until day x, Freiling will be undergoing dialysis twice a week for four to five hours.

Dialysis at Home

Christof Widera makes use of a very different type of dialysis. For him, peritoneal dialysis is the procedure of choice. Two litres of electrolyte solution enter the abdominal cavity from the dialysis bag via a catheter. The vessels of the peritoneum act as a natural membrane: toxins accumulate in Widera's

body because his kidneys are no longer working. They migrate through the peritoneum into the dialysis solution in the abdomen. After about two hours, this flows away, taking the toxins with it. In order to detoxify the patient effectively, this process must be repeated four times. Although this dialysis procedure takes eight hours, Kühne sees many advantages: "For the body, this type of dialysis is much gentler, as it is slower. Furthermore, the patient can do this alone at home and does not have to come to the hospital. One of my patients simply runs the dialysis in his office during his working hours. Especially young patients appreciate this flexibility."

There are two prerequisites for mobile dialysis: the patient must accept the technical challenges and be prepared to connect himself to the dialysis. The patient also needs enough storage space for consumables and equipment. Specialist nurse Aleksandra Taron explains: "The bags, tubes, mouthguards and disinfectants are supplied directly to the patient's home by manufacturers such as Fresenius, Baxter or B. Braun. For this the patient needs at least ten square meters of storage space. Four bags are needed per dialysis, so patients should not necessarily store them in the basement; otherwise moving them would become quite tedious. "The bags can be changed manually or connected to a dedicated device to automate the procedure.

Dialysis bags

Hygiene is of paramount importance for dialysis. This applies to the connection and disconnection of the patients to the dialysis machines, to the entire equipment and of course also to the production and filling of the bags with the electrolyte solutions. Contaminants and germs are life-threatening for patients. The bags with the dialysis solution consist of multilayer plastic. Kiefel GmbH, Freilassing, has decades of experience in the design of machines and systems for the manufacture of dialysis bags. Depending on the type of plastic, the company uses high-frequency or thermal contact welding. The systems join two layers of plastic film and produce dialysis bags from this. The machines integrate fittings on the bags during the welding process. Bag production and filling must be carried out under the highest hygiene class conditions. Optimal combinations of materials in the design of the machine are necessary, e.g. to safely avoid the formation of particles - for example from sliding friction. These could enter the human circulatory system via the dialysis bag, leading to chemical deposits or allergic reactions. The design of the systems therefore rules out the possibility of small parts getting into the bags during the assembly. This ensures the safety of the patient, which is checked internally and externally by regular quality controls.

Fact Box

Haemofiltration: The patient's blood flows through a filter membrane at a rate of at least 300 ml/min. A pump builds pressure on the blood side, so that plasma fluid from the blood is forced through the filter. This trans-membrane flow also removes the toxins accumulated in the blood. A portion of the withdrawn liquid is returned to the patient via the electrolyte solution from the dialysis bags.

Haemodialysis: The blood flows through the interior of a hollow-fibre membrane outside the body. The exterior of the membrane is surrounded by electrolyte solution. The membrane works like a filter, so it is only permeable to some of the substances. The detoxification of the patient works on the principle of osmosis: If substances are present in higher concentrations on one side of the membrane than on the other, then these migrate through the membrane, until the substance concentration is balanced. The toxins from the blood migrate into the dialysis solution, desired substances pass through the membrane into the blood of the patient.

Peritoneal dialysis: Due to its special structure, the peritoneum can be used as a "filter membrane". Dialysis solution enters the abdomen via a catheter and remains there for up to several hours. The small molecule substances can pass from the blood via the capillaries of the peritoneum into the dialysis solution. The dialysis solution must be drained after a certain time, replaced with a fresh one and the process repeated up to four times.

Shunt: It is a surgically created shorting connection between an artery and a vein and is often located on the patient's lower or upper arm. The shunt can deliver up to 500 ml of blood per minute, which a normal vein cannot even approach. Only then is dialysis by haemofiltration or haemodialysis possible