Innovation at its Best for rPET, Fiber & more at the K 2025

29 Jul 2025

With 70 years of experience and a clear perspective on the future, Kiefel is positioning itself at the K trade fair 2025 as a driver of innovation in industrial manufacturing. In Hall 3 / D90, the specialist for thermoforming and joining technologies will impress with a broad portfolio for the packaging, medical & pharmaceutical, appliance and service sectors – and will add special focal points with two technology solutions.

“The K trade fair 2025 is a strong signal for us: 70 years of Kiefel stand for experience, and, especially for constant change. Our solutions combine efficiency, sustainability, and digitalization and offer customers worldwide real added value in a dynamic market environment."

Sven Engelmann, Vice President - Technology

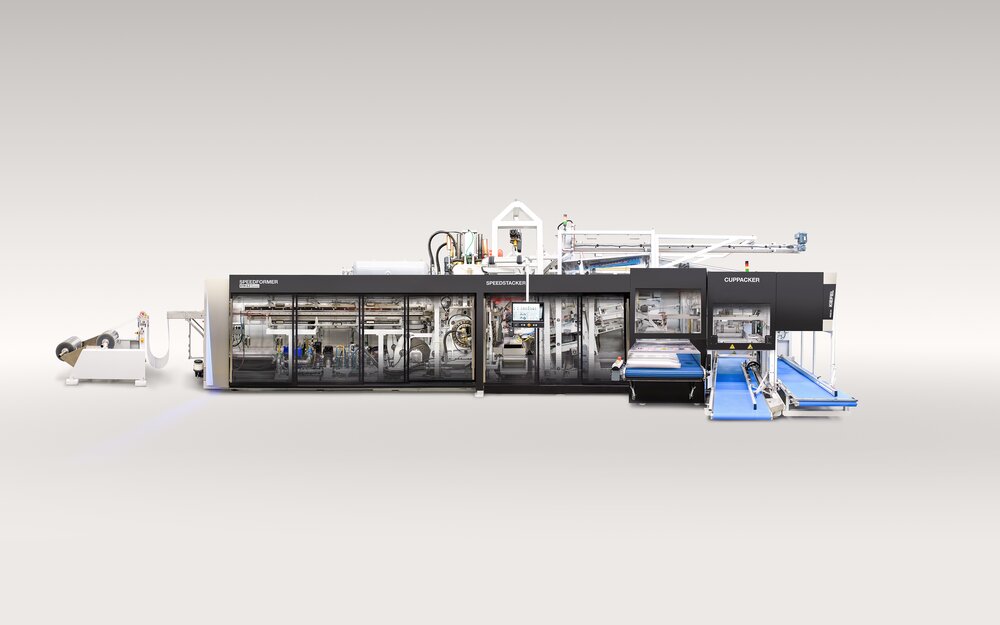

Highlight 1: New SPEEDFORMER KTR 6.2 Speed sets standards in thermoforming

Kiefel is presenting the SPEEDFORMER KTR 6.2 Speed tilting machine at K live, a new generation of thermoforming, which optimizes both material consumption and line performance. The machine produces high-quality cups, from a range of materials including recycled PET. Various rPET materials were tested in advance in close collaboration with film partner Coexpan. At the Kiefel booth, visitors will gain exclusive insights into test results – and see how recyclability and high-quality design can be ideally united in cup production. Recycling meets high-tech: A second life – in a better shape.

Technologically, the machine excels with several newly developed features with patents pending. These include the intelligent SpeedGuard™ film guide and the high-performance

ProSpacing™ system, which ensures higher output even when handling varying product geometries. In short: These solutions offer a unique combination of automation, efficiency and flexibility for customers, in keeping with the company slogan - Driving your performance.

In addition, visitors can experience the digital twin of the machine live at the Siemens booth (Hall 3, Stand D16) and see for themselves the practical advantages of holistic project support.

Highlight 2: Fiber Packaging taken to the next level – with two technologies

Kiefel is once again demonstrating its pioneering spirit in the natural fiber sector: Visitors can watch live as the NATUREFORMER KFT Lab produces highly functional margarine shells from pulp using the new Double-Dip Process in the wet fiber process. The food-compliant packaging thus gains superior barrier properties for oils and fats through mono-material layers – whilst being suitable for recycling in the circular economy.

Kiefel is presenting a further example of innovation, its new dry-fiber technology: market-ready applications such as trays, beverage lids and technical packaging are produced directly from paper off the roll – an efficient solution with an impressive annual output of up to 70 million pieces for the most common requirements. Combined with the wet-fiber process, this shows that sustainability is not a rigid concept, but requires intelligent, complementary technologies, tailored to each application.

Insights & equal partners in development

Kiefel is a holistic systems provider, supporting its customers from the initial idea to series production. In order to make this co-creation even more intensive in the future, the company is expanding its Customer Innovation Centers worldwide. At the trade fair, visitors will gain initial insights into the expanded possibilities – from material testing to design and process development to the market-oriented implementation of individual product ideas.

Further topics at the stand

Aside from the highlights already mentioned, Kiefel will also be providing information in Hall 3 / D90 about solutions for medical technology, digital services such as the optimized digital Kiefel Portal and individual projects in the field of refrigerator and large-scale thermoforming systems – a holistic systems approach that ensures competitive advantages for customers worldwide. Kiefel is an active member of the VDMA, and will be presenting another product made from recycled plastic material in the VDMA pavilion. A product pitch on October 9 will provide an opportunity to learn more about the technology and its potential for a circular economy.

Future. Made by Brückner Group

As part of a leading global group of companies, Kiefel builds on a strong foundation of shared expertise and innovation. United by a common vision, the Brückner Group aims to shape global markets and the future of plastics and materials processing with sustainable solutions that are flexible, fast and customer-oriented. To make this common goal tangible, the Brückner Group and its business units will be represented at a joint stand for the first time. This presentation offers customers and stakeholders the opportunity to experience the combined strength of the globally active companies in the fields of plastics and alternatives, packaging and technical applications, machinery and production systems, as well as a holistic range of solutions.

Each business unit contributes cutting-edge technologies for future-oriented markets that embody the Brückner Group's shared commitment to sustainability, digitalization and technology leadership. From more efficient production technologies and intelligent automation to new packaging approaches and digital interfaces, these innovations reflect a shared drive to move forward with a clear purpose.

Together they stand for collaboration, excellence and bold vision: shaping the industry of today and tomorrow.