The Next Generation of the KTR 5.2 Speed Cup-forming System from Kiefel at the K 2019

30 Sep 2019

KTR 5.2 Speed of KIEFEL: Integrated Optimization for more Quality and Efficiency!

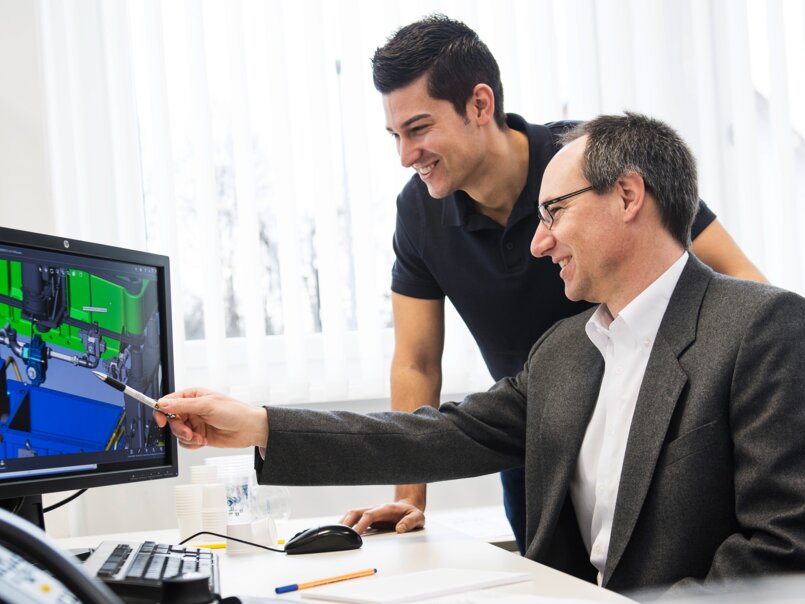

Enhancing production and efficiency - the thermoforming specialists at KIEFEL GmbH, Freilassing, have focused on the continued development of the tried-and-tested cup-forming machines for the KTR 5.2 Speed.

An integrated approach has allowed Kiefel to succeed in achieving its goals. Christian Stockinger, Head of Engineering & Design at Kiefel Packaging, explains: "The new generation KTR 5.2 Speed excels with higher output, lower energy consumption, and shines with robust machine design and intuitive user guidance. Despite achieving a significant increase in performance, we have not had to increase the footprint." Experience the new generation of KTR 5.2 Speed at the Kiefel booth during K 2019, Hall 3, Stand E 90.

Optimizations along the entire KTR 5.2 Speed cup-forming system ensure considerable performance enhancements and process improvements: Starting with film transport via the heating, forming station, forming air supply, tool cooling, tooling and tool change through to the new stacking system with downstream automated carton packaging.

Forming Station Upgrade

A sophisticated dimensioning of complete kinematics improves drivetrain rigidity whilst reducing vibration throughout the system. In addition, the new motor-gearbox combination permits up to 50 cycles per minute and increases the punching force to 400 kN. The new backlash-free upper yoke adjustment rounds off the new robust forming station. The enlargement of the usable forming surface results in an increase in the number of cavities in the tool; Optimized rapid tool change reduces downtime.

Flow-optimized forming air lines fill the cavities consistently and reduce the filling time by 25 percent and the venting time by 30 percent.

Focus on Efficiency

A long heater ensures a precision heat distribution, perfect for PP and multilayer films. The result is highest product performance: high-transparent PP cups and an optimized material distribution.

The nominal heating capacity has been reduced by about 15 percent whilst maintaining the heat input. Stockinger explains how this was achieved: "In order to optimize the heat output, we have reduced the distance between the heating elements and the film, insulated the heating elements even better and improved the temperature and process control."

The new tool cooling system is fully automatic and sensor-controlled, reducing energy losses. This innovation also has a positive effect on tool life and product quality. The KTR 5.2 Speed utilizes two separate cooling circuits for the upper and lower tool and an extended sensor system for optimum control. Two high-pressure pumps and mixer valves supply the two circuits with cooling water; the integrated temperature control ensures optimal tool protection. Start automation is sensor-controlled, completely preventing overshooting of the lower tool.

Innovative Film Conveyor

The new, gentle film guide avoids scratches, particles on the film and the loss of contact heat. The threading of the film is greatly improved thanks to excellent ergonomics and the new geometry at the infeed table. Start automation prevents cold film from spreading. The linear guides ensure optimum film spreading, strain relief is provided by separable movements, manual height adjustment and position control are handled by the initiator. Spreading increases before the forming station. The system also works robustly in case of film shrinkage. New lubrication points for tabs and chains as well as the continuous lubrication of the chains prevent the lubricant from reaching the film. The new film transport system ensures food safety whilst optimizing film orientation and product quality.

New Stacking with a Uniform Design

The SPEEDSTACKER is designed to stack a wide variety of plastic articles. It achieves a remarkable increase in maximum article height compared to the previous model. In addition, the system has achieved a significant increase in cycle speed. The focus is on usability: Operation and maintenance of the SPEEDSTACKER are simple; format changes are quick, safe and ergonomic. The compatibility of the SPEEDSTACKER with existing format parts is particularly noteworthy. Control of the entire system KTR 5.2 including the SPEEDSTACKER via only one control panel makes operation even easier. This means that articles are stacked easily, quickly and flexibly.

New Intuitive User Interface KMI2.0

Simple and intuitive, that is the motto of human interaction with the KTR 5.2 Speed. Pictograms and graphics support the input of machine parameters and aid fault diagnosis and rectification as well. The display shows the entire forming process at a glance, important functions are just a click away. This makes the complete process easy to understand, even for non-experts.

Kiefel has paved the way to a new level of user-friendliness together with numerous partners. Customer needs were assessed and evaluated with universities, internal and external experts, and further developed to produce a new HMI system.

In addition to the more technical aspects such as a shorter training period, quick recipe optimization and fast troubleshooting, the user experience played a significant role in the new development. Especially in the age of Industry 4.0, the pleasure of working with high-tech machines should not be neglected.

Stockinger is completely satisfied with the result of the new development: "Not only have we made a multitude of little improvements, but we can offer our customers genuine innovation. In practice, this means more output for the customer in combination with lower resource consumption.