Elevating efficiency in polymer cup production:

SPEEDFORMER KTR 6.2 Speed

Order now!

Up to 50% more output at the same footprint & quality

This advanced SPEEDFORMER KTR 6.2 cup forming machine sets the standard for efficiency, delivering up to 50% higher output of high-quality cups and coffee capsules compared to other machine manufacturers.

Profit from 10% energy savings due to optimized heating. The external insulation of the radiant heaters further increases the efficiency of the machine, not only saving costs, but also improving your ecological footprint.

Key highlights KTR 6.2 Speed

Enhanced Productivity

Enhanced Versatility

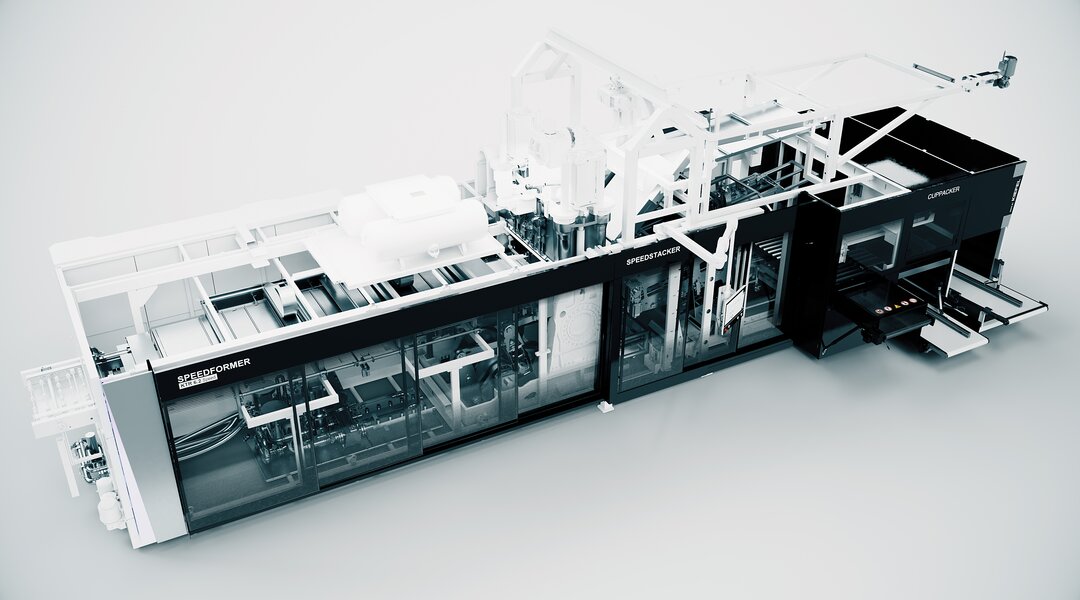

A first preview of the SPEEDFORMER KTR 6.2 Speed

Benefits at a glance

Stronger punching force

The KTR 6.2 Speed offers an impressive punching force of 900 kN and is characterized by its flexibility in material selection.

Whether thin or thick films, they are no obstacle for the KTR 6.2. It can easily punch a wide variety of materials, including PET, which require stronger punching forces and can also punch across the entire forming area.

Advanced stacking & automation solutions

Increase your production output with our two innovative modules for efficient stacking and downstream automation: The SPEEDSTACKER and the CUPPACKER. They offer fully automatic stacking and packaging with optimized product transfer that uses real-time monitoring to guarantee maximum cycle times and smooth machine movements.

Benefit from maximum flexibility in the design of your product geometries while achieving maximum output quantities thanks to efficient stacking in the SPEEDSTACKER and packaging in the CUPPACKER.

Intelligent cooling system

Your end products are formed with greater precision and faster cycle times thanks to our optimized technology: The improved energy dissipation in the tooling ensures faster uniform cooling. Additionally the improved forming air system drastically reduces the filling time which leads to higher output.

This gives you consistent quality and increased efficiency in your production.

Intuitive machine operation

Our intuitive user interface makes your thermoforming processes easier and supports you in many ways. From a short training period and fast recipe optimization to efficient error handling and a targeted maintenance system - with KMI 2.0 you can immerse yourself in the world of thermoforming 2.0 and experience a new dimension of user-friendliness.

Key figures

|

Max. forming area |

840 x 585 mm |

| Punching force | 900 kN |

| Cycle speed | 45 cycles/min |

| Max. height of formed part | 250 mm |

| Max. film thickness | 3,5 mm |

| Energy savings due to insulated heater | 10 % |

Comprehensive support from Kiefel

As a leading turnkey supplier in the packaging industry, Kiefel offers comprehensive automation solutions tailored to your production requirements. From film to carton, we provide tailored stacking and packaging automation solutions for your SPEEDFORMER KTR, ensuring seamless integration and optimized performance throughout your manufacturing process.

Get in touch

Contact us today to discover the benefits of the SPEEDFORMER KTR 6.2 and elevate your efficiency in cup forming and beverage packaging. Let us partner with you to drive success and innovation in your manufacturing journey.

Arrange your consultation appointment now

for your innovative packaging solution