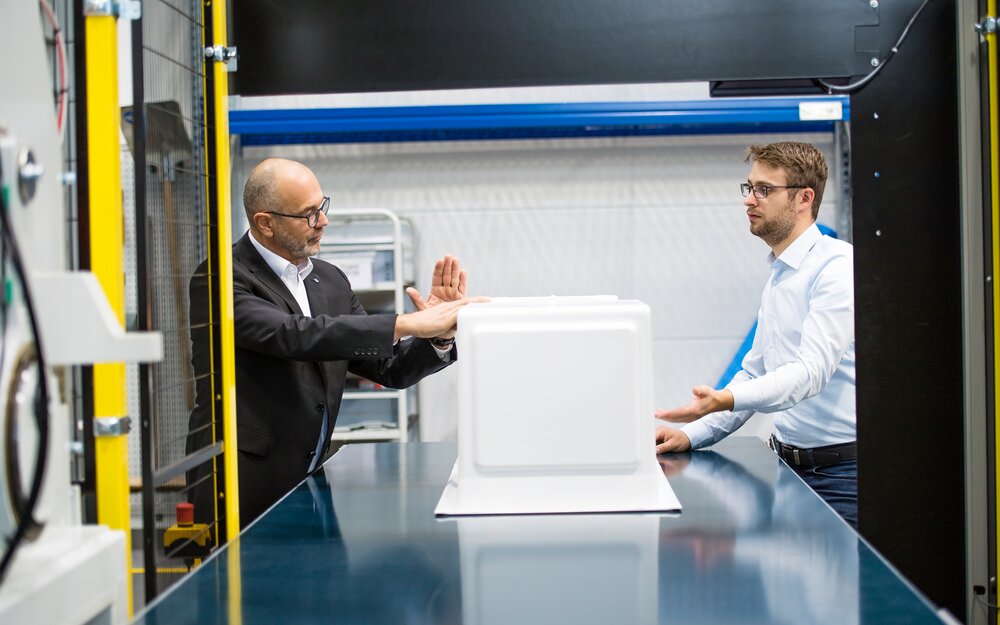

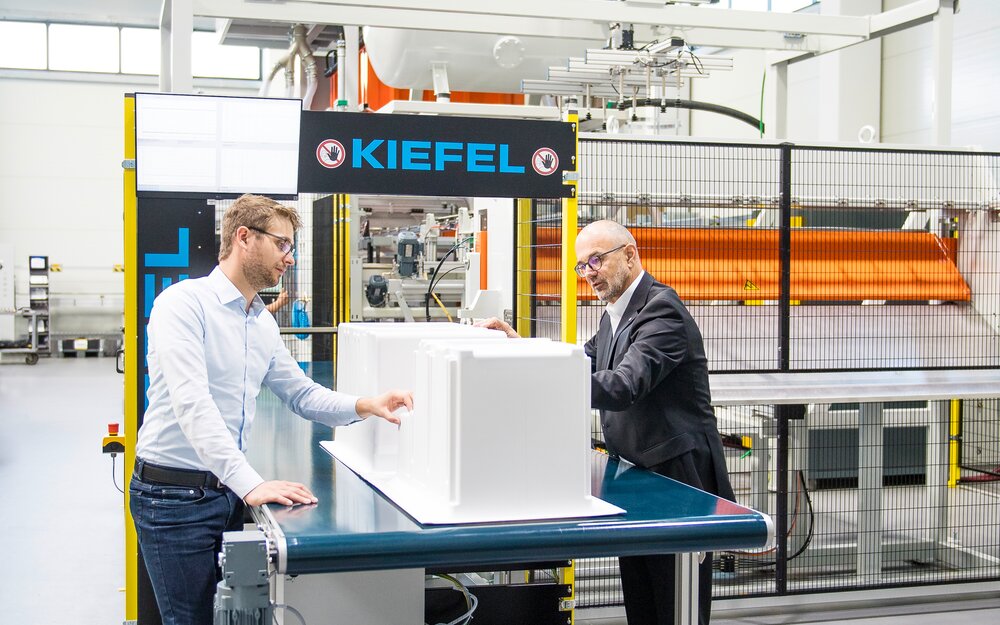

Machines for the production of refrigerator components

Interior or door liners of refrigerators or freezers

One of the main focuses of our forming technology is machines for the production of refrigerator components.

Whether for refrigerators or freezers, whether inner or door liners, whether single or combined, even complex shapes and designs can be processed with the most intelligent solutions thanks to the powerful thermoforming machines.

The production of inner door liners is carried out from plastic rolls, plastic plates are used for the production of inner containers.

For high-quality production of inner door panels and inner containers, the so-called air pressure forming process is used as standard.

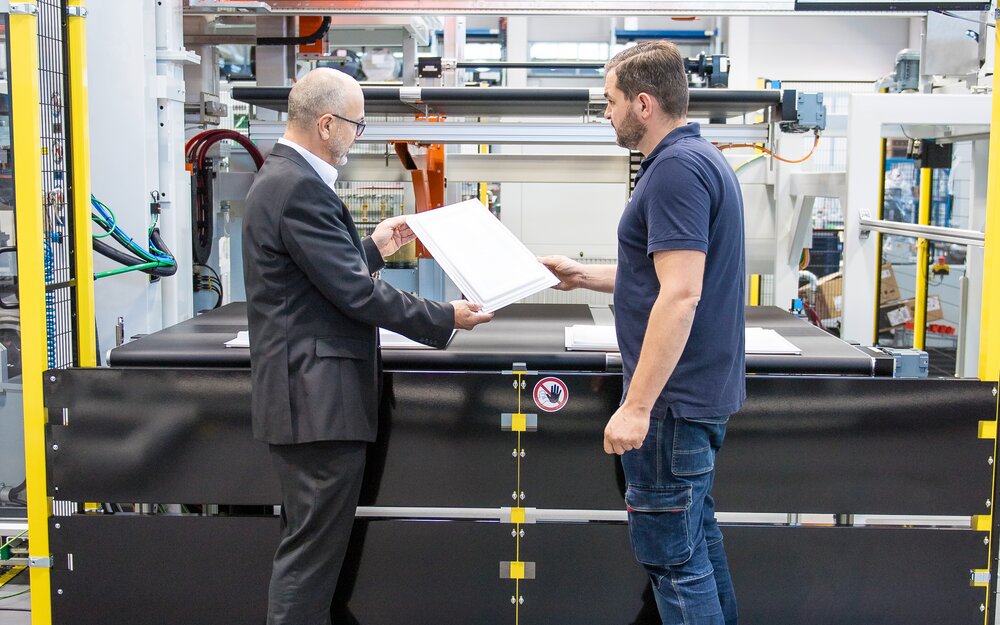

SHARPFORMER KID SPEED

For high quality inner doors

Why SHARPFORMER KID SPEED?

Material and cost savings

Lower parts price by up to 20%

Maximum output & efficiency

High-pressure forming and cutting in one step

Highest product quality

High quality cutted parts

Efficient & sustainable

Lower energy costs & small footprint

Max. machine availability

Inner liners

Fast in-feed and optimized cooling to reduce machine cycle time

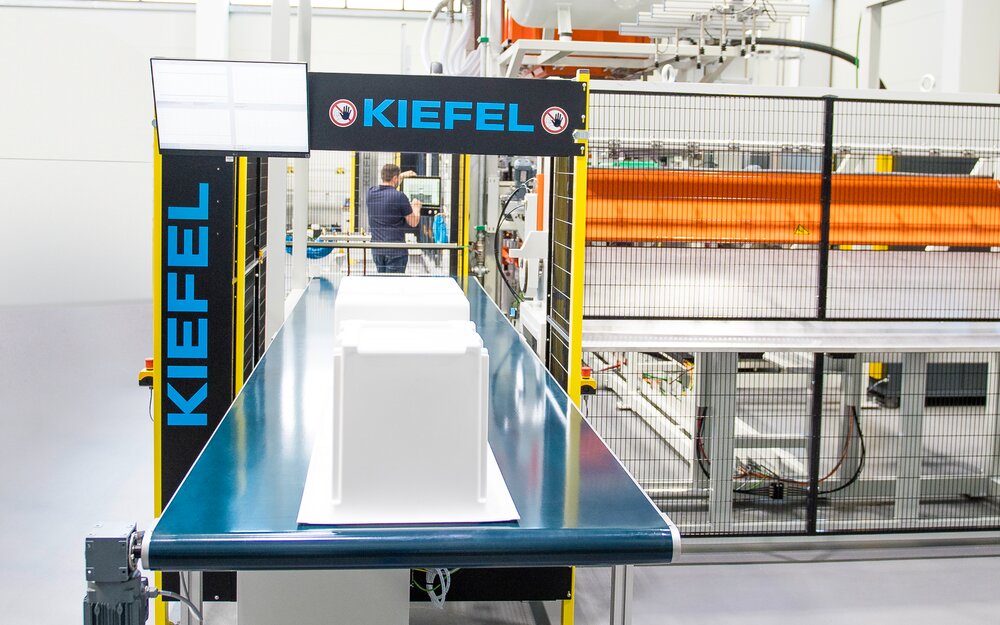

SHARPFORMER KID PREMIUM- & SMART

SHARPFORMER KID PREMIUM & SMART series stand for high quality and flexible thermoforming machines - designed for the production of high quality inner linings for popular refrigerators.

The SHARPFORMER KID PREMIUM is particularly suitable for small and medium-sized European refrigerators. For French Door appliances and American side-by-side refrigerators, the SHARPFORMER KID SMART is the perfect choice.

The specific modular concept and the improved vacuum pressure forming technology enable higher production speed of refrigerator inner liners made of HIPS or ABS material.

The entire production process includes loading the plates from the stack, heating, forming and final cutting of the parts.

Your Kiefel benefits:

- Reliable chain rail sheet transport system: Narrow material clamping & compact construction, thereby use of smaller plastic plates possible

- Full process control for best product quality: Combined diagrams with all important process parameters

- Optimized heating with improved energy efficiency & fast heating adjustment

- Precise measurement of bubble height for optimum material distribution: Laser measurement of bubble height, fixed or with motorot-driven positioning

- Pressure bell locking and sealing system: Patented locking system combined with solid soft contact seal; no deformation of the frame due to reduced clamping forces

- Low-noise machine design to reduce the health risk for operators

Versions of the SHARPFORMER KID PREMIUM & KID SMART

| KID PREMIUM 1.000 | KID SMART 1.250 | |

|---|---|---|

| Forming area max. | 1.000 x 2.200 mm | 1.250 x 2.100 mm |

| Forming area min. | 500 x 750 mm | 500 x 750 mm |

| Forming height max. | 800 mm | 800 mm |

| Film thickness | 1,0 - 5,0 mm | 1,0 - 5,0 mm |

| Production speed max. | 200 cycles/hour | 150 cycles/hour |

Inner liners

High efficiency & special door liner machine

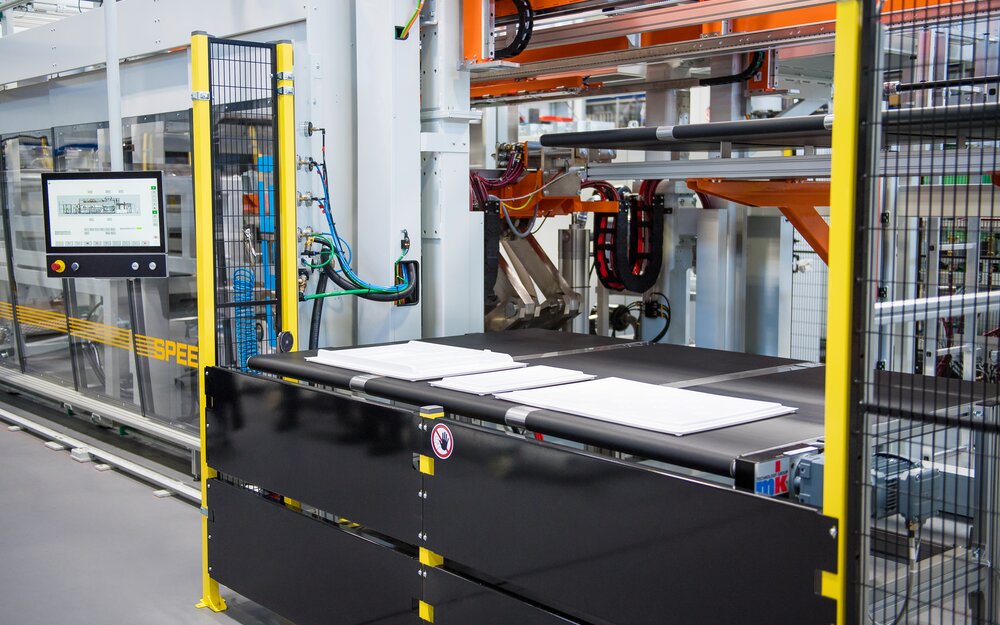

SHARPFORMER KID SPEED

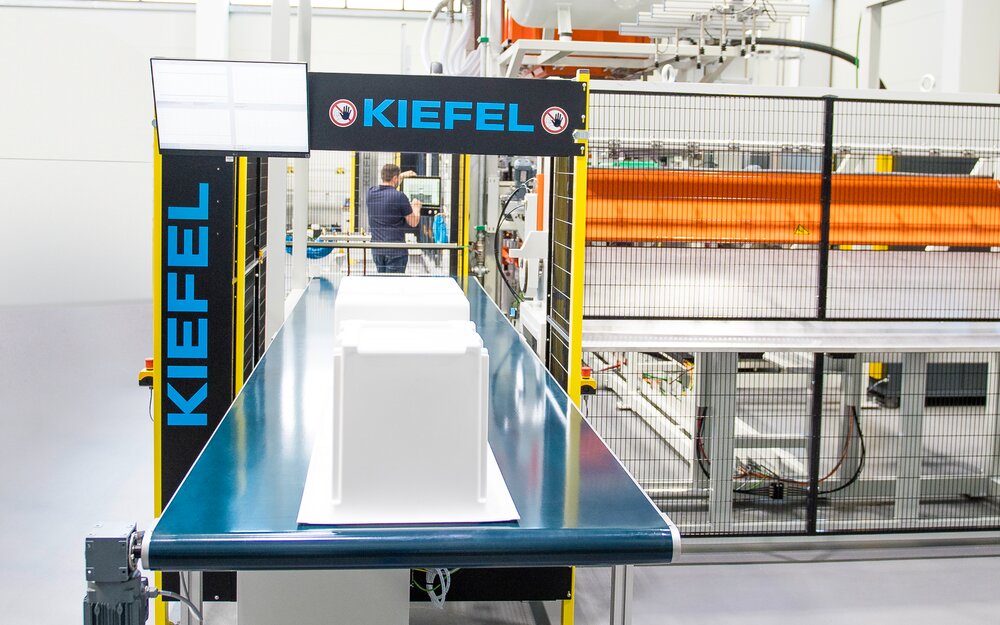

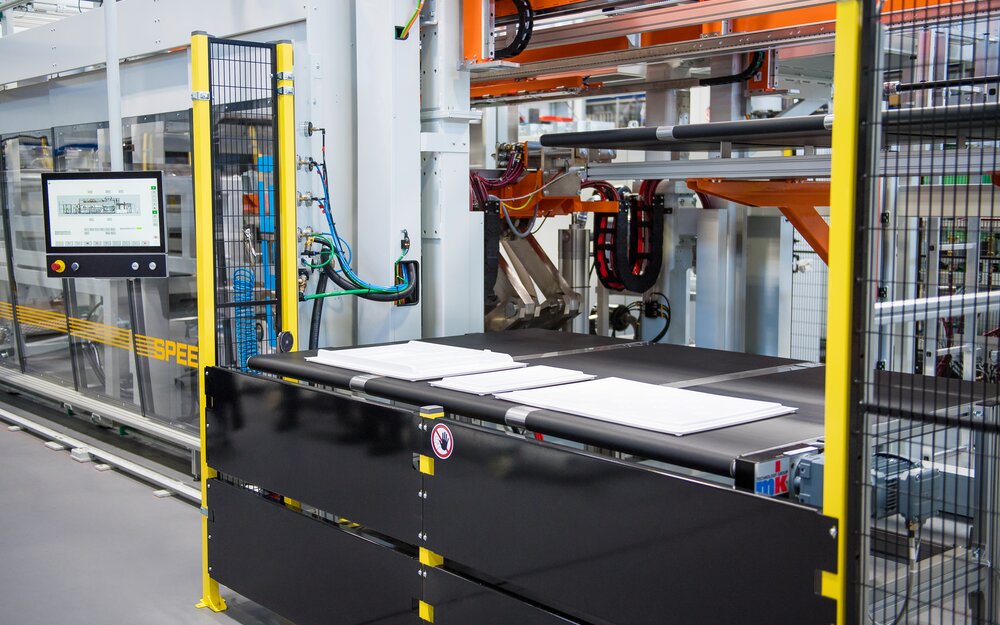

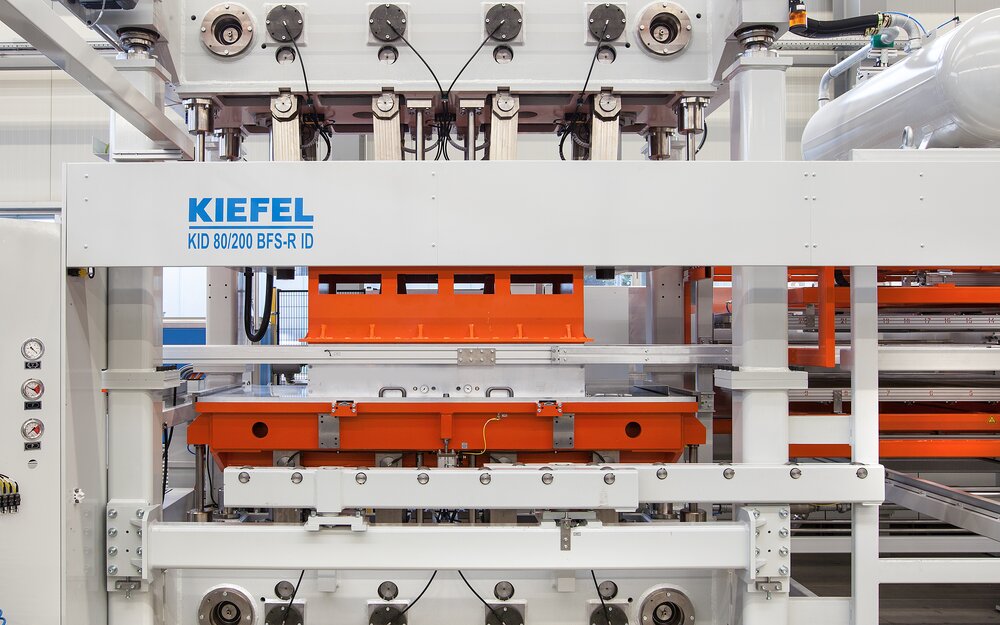

The new generation of inline thermoforming machines - the SHARPFORMER KID SPEED series - has been dedicated to the high-performance production of door panels made of HIPS or ABS materials.

The proven Kiefel thermoforming technology with its machine engineering features reduces the total cost of ownership.

The overall process includes automatic unwinding of the plastic film from the coil, heating, forming and cutting in place, as well as unloading of the product.

Your Kiefel benefits:

- Reliable chain transport system for plastic films: Narrow material clamping and compact design -> use of narrower plastic film rolls possible

- Optimized heating with improved energy efficiency & fast heating adjustment

- Up to 20% less material with better quality through high-pressure thermoforming: Higher material tension strength due to low deformation temperatures

- Higher output due to multi-cavity forming tool with up to 6 cavities per tool, thus increasing the output from 300 to 1800 pcs/hour

- Forming & cutting in one cycle: Forming tool is equipped with knives and cutting plates, for accurate trimming after forming

- Low-noise machine design to reduce the health risk for operators

Versions of the SHARPFORMER KID SPEED

| KID SPEED 1.000 | KID SPEED 1.100 | |

|---|---|---|

| Forming area max. | 1,000 x 2,200 mm | 1,100 x 2,200 mm |

| Forming area min. | 420 x 1,150 mm | 420 x 1,150 mm |

| Forming height max. | 150 mm | 150 mm |

| Film thickness | 0,8 - 1,8 mm | 0,8 - 1,8 mm |

| Production speed max. | 300 cycles/hour | 300 cycles/hour |