Speedformer KMD 78.2 Speed – Launch of a new generation -Thermoforming Simplified

04 Jul 2019

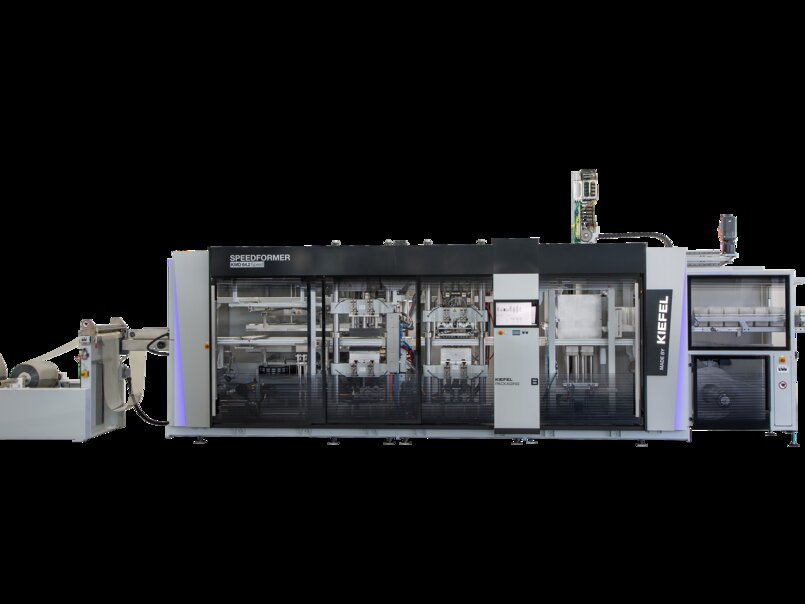

What happens when designers of KIEFEL GmbH, Freilassing, unite essential customer requirements with regard to steel rule machines? The Speedformer KMD 78.2 Speed is born! Let us take your breath away at the K 2019 in Düsseldorf at the Kiefel booth in hall 3, stand E90. Experience the Speedformer KMD 78.2 Speed performing live. The new generation of Kiefel steel rule machines offers the usual quality with even greater productivity and energy efficiency.

Erwin Wabnig, Director Packaging Division at Kiefel, explains: "The new generation of machines is fast and reliable. Operators, even without specific training, can operate them intuitively. Ergonomics and data transparency are a matter of course. And of course, in addition to common materials and products, our new system can also process novel film materials and produce even complex products whilst consuming a minimal amount of energy."

Behind the Scenes of the KMD 78.2 Speed

The Kiefel designers focused on higher productivity, process control and availability, as well as trend-setting intuitive user guidance with considerable added value in operation and maintenance. The heating system is ready for use within a very short time and excels with a 20% higher heating capacity - despite reduced energy consumption! In combination with the servo drives' energy recovery system this leads to considerable energy savings.

The new KMD generation not only saves energy, but film too! A newly developed film feed table safely and gently guides the film to the film transport system. The proven station drives stabilize and work symmetrically. The further optimized forming air vacuum system enables customers to produce superior molded parts. The ergonomic tool change systems can significantly shorten set-up times. The many improvements and details add up to significantly increase the up-time of the KMD 78.2 Speed.

Intelligent User Guidance

Simple and intuitive, that is the motto of human interaction with the KMD 78.2 Speed. Pictograms and graphics, some animated, support the adjustment of machine parameters - and if necessary they aid fault diagnosis and rectification as well. The new KMD generation only needs a few parameters to be input, the rest are automatically determined by installed algorithms. The display shows the entire forming process and other important processes at a glance, important functions are just a click away. This makes the complete process easy to understand, even for non-experts.

Kiefel has paved the way to a new level of user-friendliness together with numerous partners. Erwin Wabnig explains: "In order to optimally adapt the new KMD generation for our customers, we have increased our requirements. On this basis, we have developed a state-of-the-art system in cooperation with universities, internal and external experts that simplifies our customers' daily manufacturing."