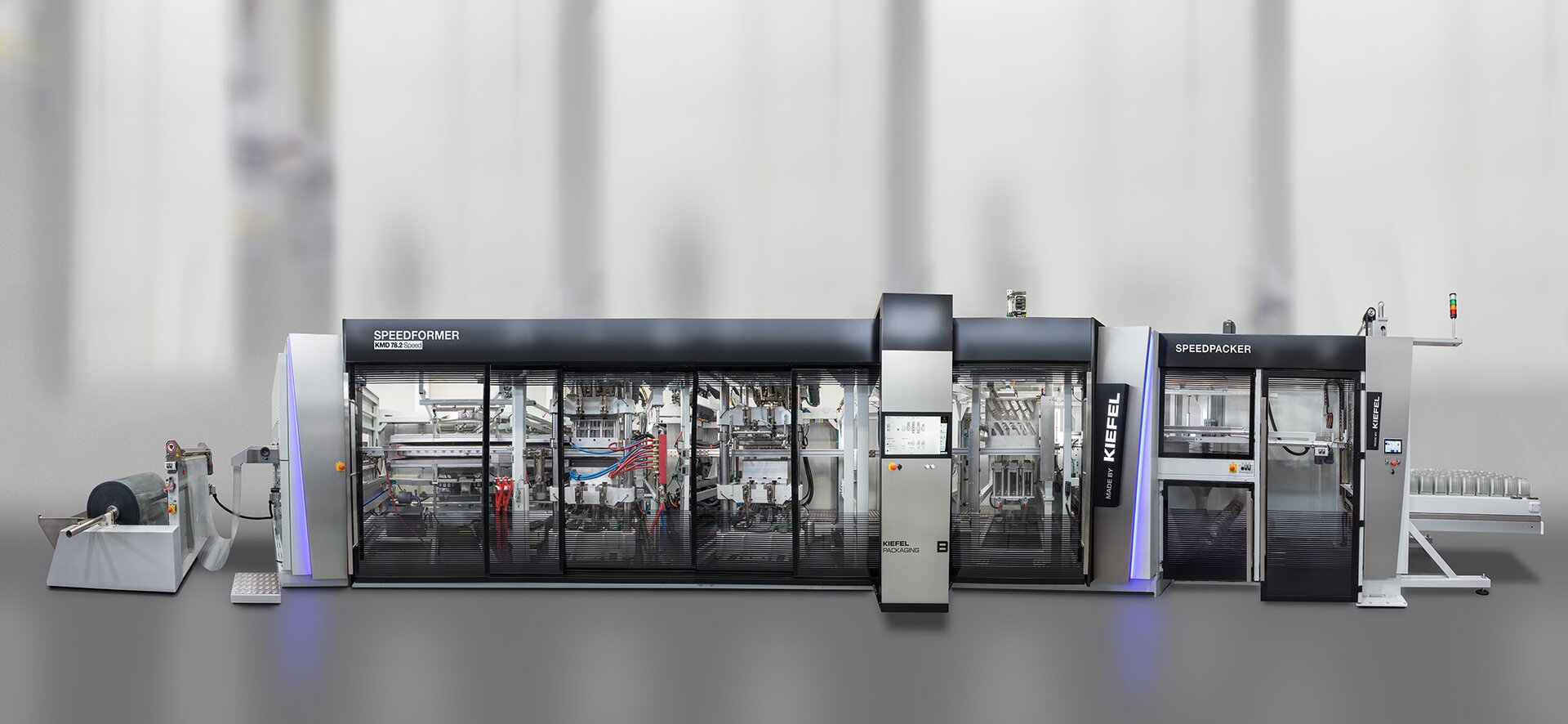

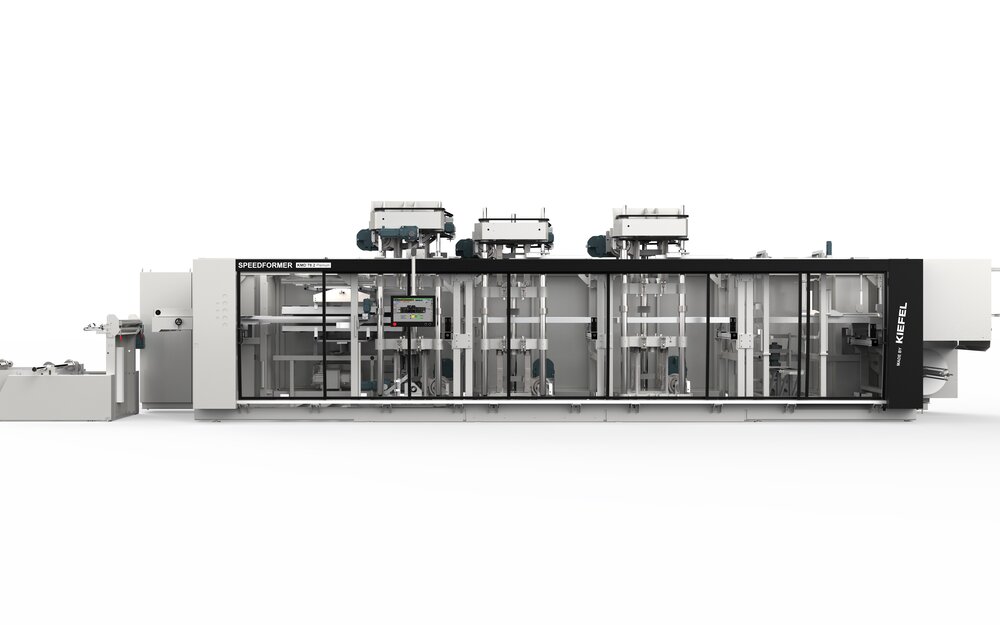

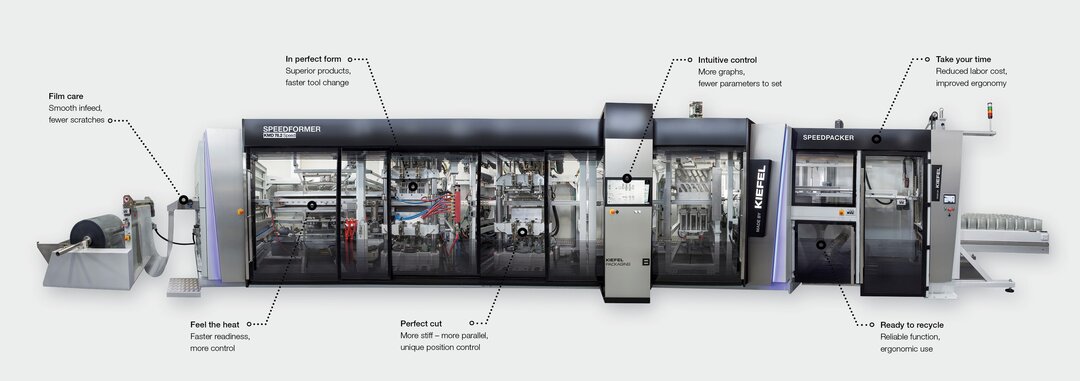

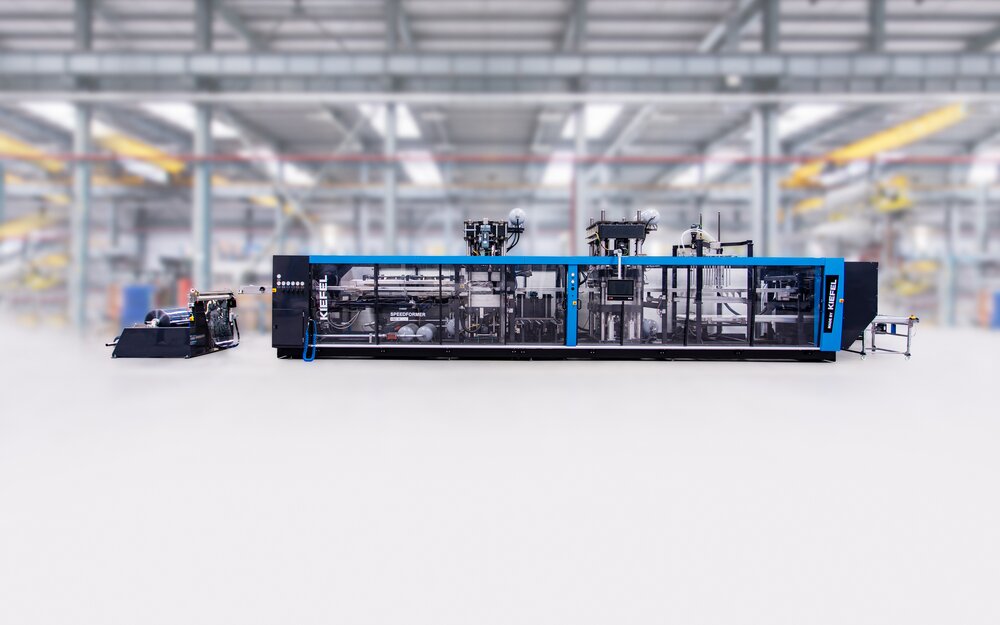

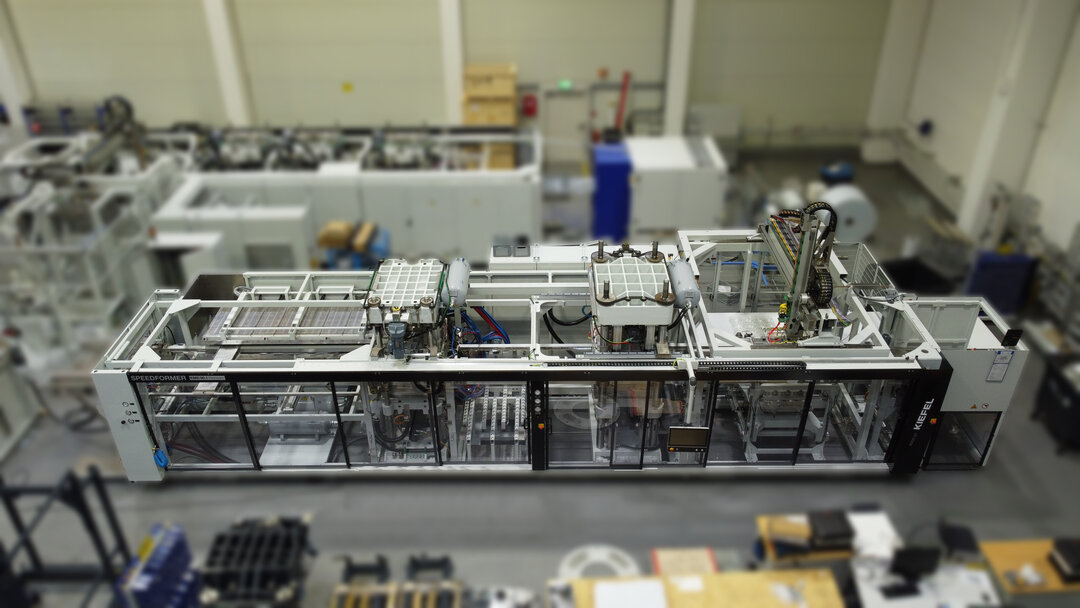

SPEEDFORMER KMD

Thermoforming at its best: Maximum Output and Efficiency

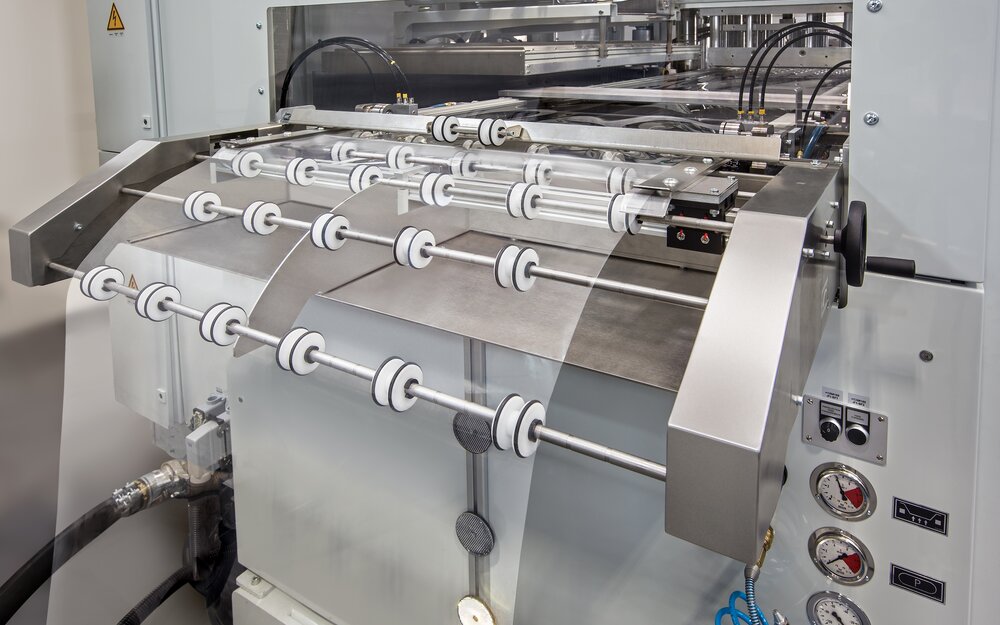

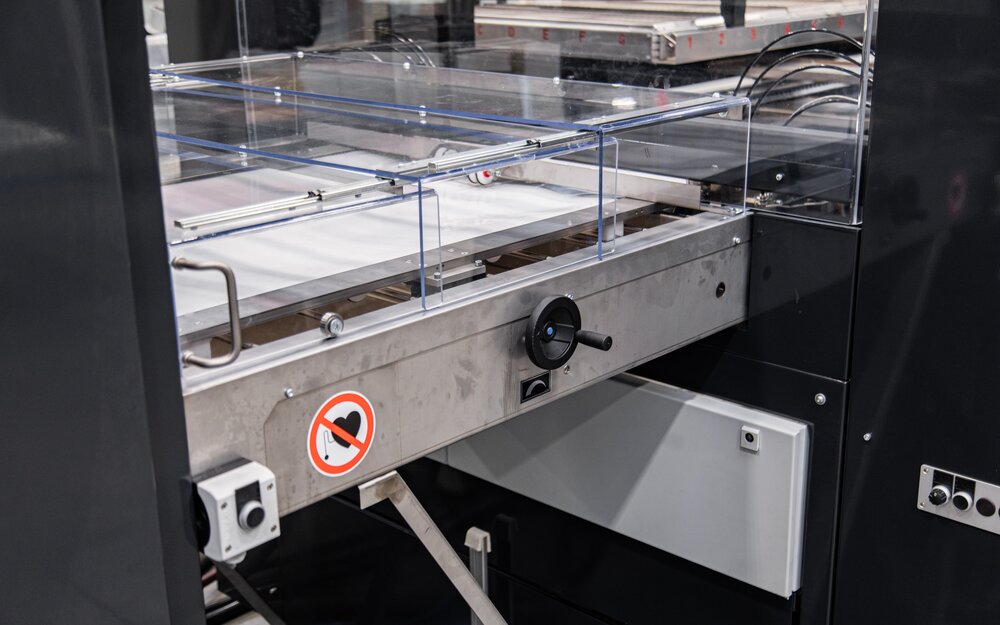

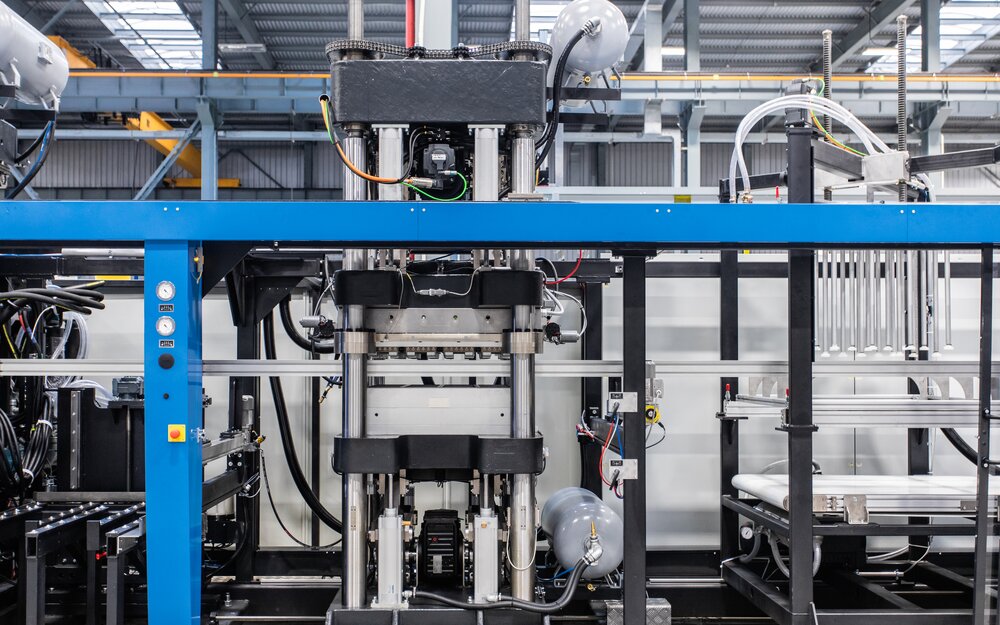

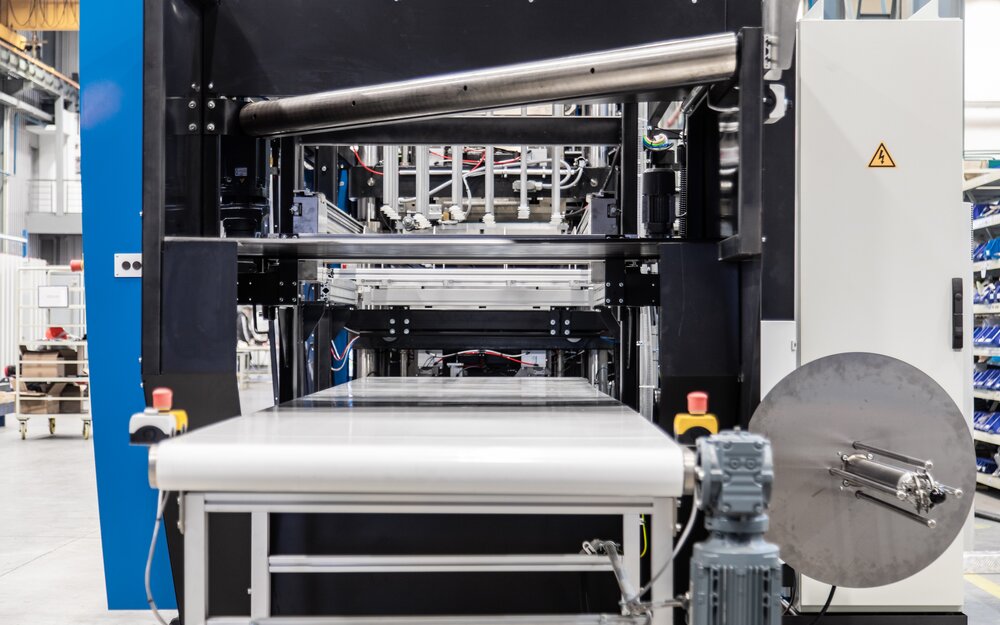

Steel rule cutting machines of the SPEEDFORMER KMD series are effective in mass production and economical even for small quantities. They can be deployed flexibly, whether in the food or non-food sector, and are versatile for materials such as (r) PET, C-PET, PP, PS, PLA, PE. The modular design offers maximum flexibility.

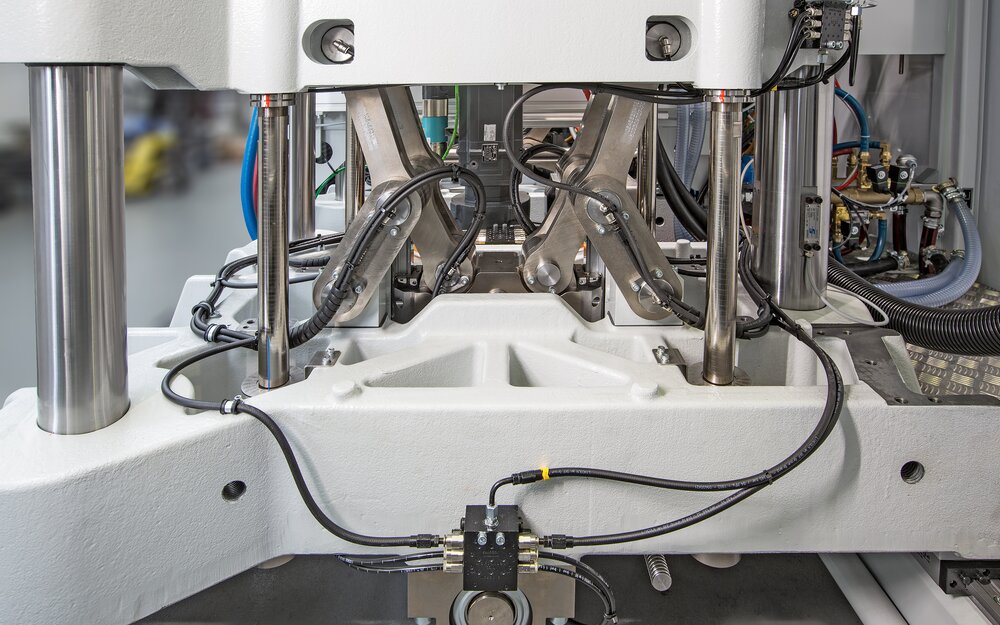

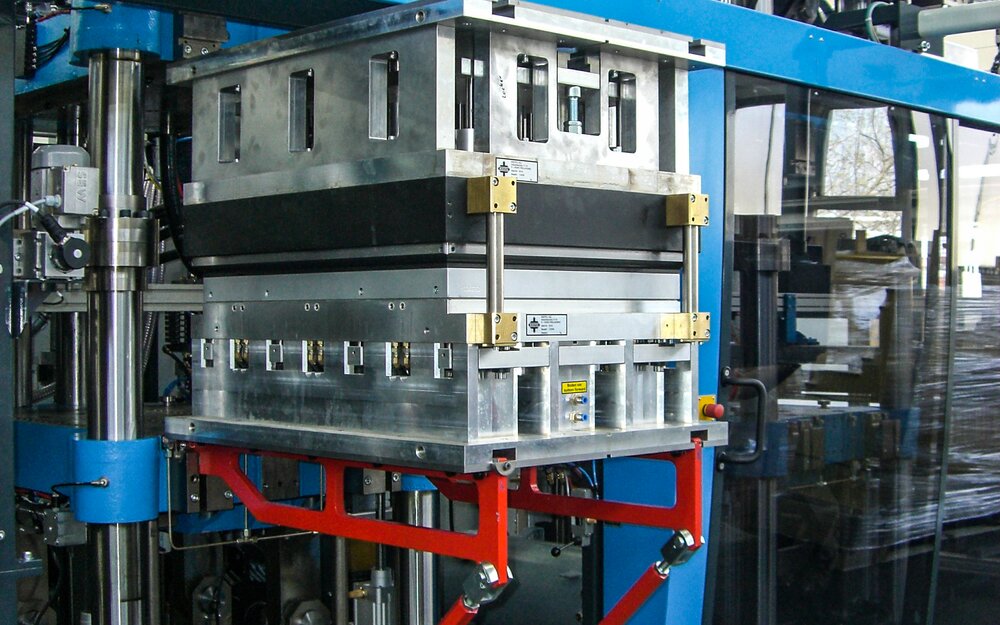

The high degree of automation and the sophisticated tool change are as much part of the mature concept as the steel rule cutting and the integrated stacking station.

Robust and precise, whether as a standard system or expanded with options. Simple and safe operation.

Kiefel is your reliable partner for turnkey solutions:

First class thermoforming equipment – cost saving automation – premium steel-rule cutting tools

Explore the KMD 78.2 Speed

Why SPEEDFORMER KMD?

Maximum output & efficiency over the entire lifecycle

Maximum machine availability & precision

Highest product quality & material saving

Efficient & sustainable

Models of the SPEEDFORMER KMD

| KMD 64.2 Speed | KMD 78 Smart |

KMD 78.2 Premium | KMD 78.2 Speed | KMD 78.2 Power |

KMD 85 Speed | KMD 90 Smart | KMD 90.1 Premium | |

|---|---|---|---|---|---|---|---|---|

| Forming area max. | 620 x 470 mm | 760 x 580 mm |

760 x 580 mm | 760 x 580 mm | 760 X 580 mm | 825 x 675 mm |

870 x 920 mm | 870 x 920 mm |

| Tool dimensions max. | 640 x 490 mm | 780 x 600 mm |

780 x 600 mm | 780 x 600 mm | 780 x 600 mm | 850 x 700 mm |

890 x 940 mm | 890 x 940 mm |

|

Height formed part max. |

120 mm | 150 mm | 150 mm | 120 mm | 120 mm | 150 mm | 160 mm | 160 mm |

| Film width max. | 670 mm | 810 mm | 810 mm | 810 mm | 810 mm | 900 mm | 925 mm | 925 mm |

| Film thickness | 0,2 - 1,8 mm | 0,2 - 1,8 mm | 0,2 - 1,8 mm | 0,2 - 1,8 mm | 0,2 - 1,8 mm | 0,2 - 1,8 mm | 0,2 - 1,8 mm | 0,2 - 1,8 mm |

| Punching force BFS | 500 kN | 450 kN | 550 kN | 650 kN | 650 kN | 800 kN | / | / |

| Punching force punching station | 500 kN | 500 kN | 550 kN | 600 kN | 600 kN | 800 kN | 850 kN | 850 kN |

| Production speed max. | 50 (BFS: 45) c/min | 40 (BFS: 35) c/min | 45 (BFS: 40) c/min | 50 (BFS: 45) c/min | 50 (BFS: 45) c/min | 45 (BFS: 40) c/min | 30 c/min | 30 c/min |

SPEEDFORMER KMD 64.2 Speed

Innovative model for smooth production

Benefit from the new generation KMD 64.2 Speed. The innovative machine series better meets your production needs by enabling tailor-made configuration with proven up stacking and pick & place stacking

Your Kiefel benefits:

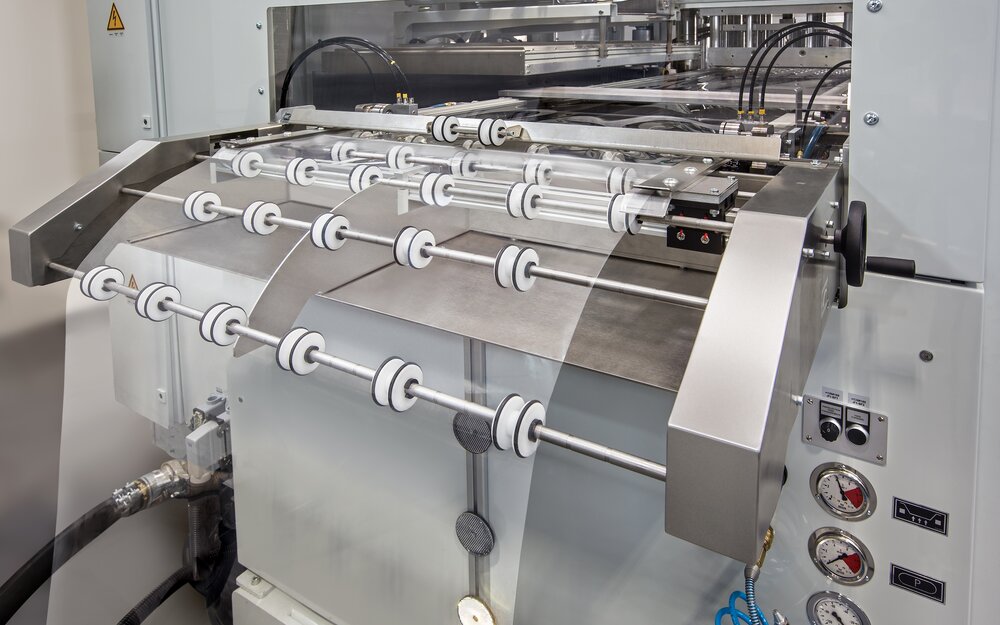

- Performance and process control: Optimized forming, better cutting, smoother production

- Machine availability: Faster & ergonomic tool change, faster heater production readiness

- Efficiency & sustainability: More heating power - less consumption, intelligent lubrication system.

- Easy operation & maintenance: New HMI generation - intuitive operation, reduced input parameters, guided maintenance

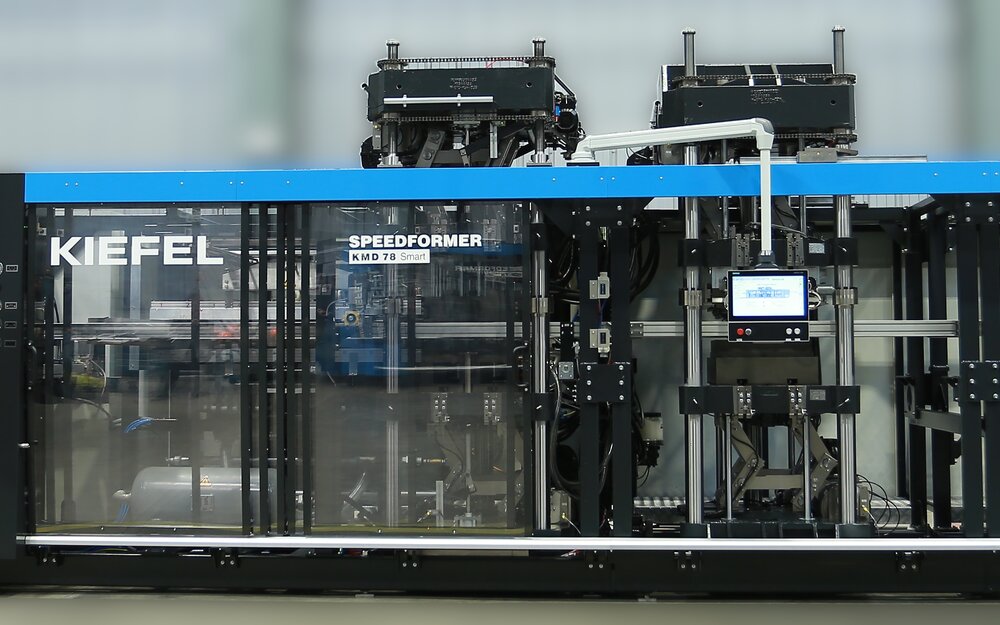

SPEEDFORMER KMD 78 Smart

German-Chinese success story with customer in focus

The KMD 78 Smart combines proven German technology with local manufacturing and technical support in China - a German-Chinese success story, 100% made by Kiefel. All engineering standards and quality processes are applied in China, guaranteeing the highest level of satisfaction.

The KMD 78 Smart is available for many countries - just contact us and find out which model best fits your requirements and get a quote.

Your Kiefel benefits:

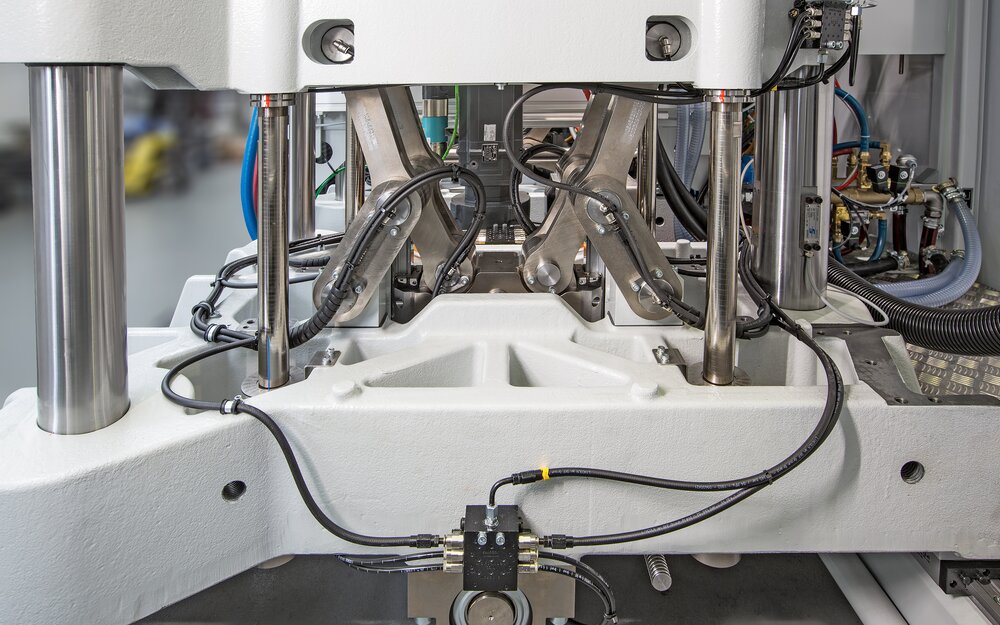

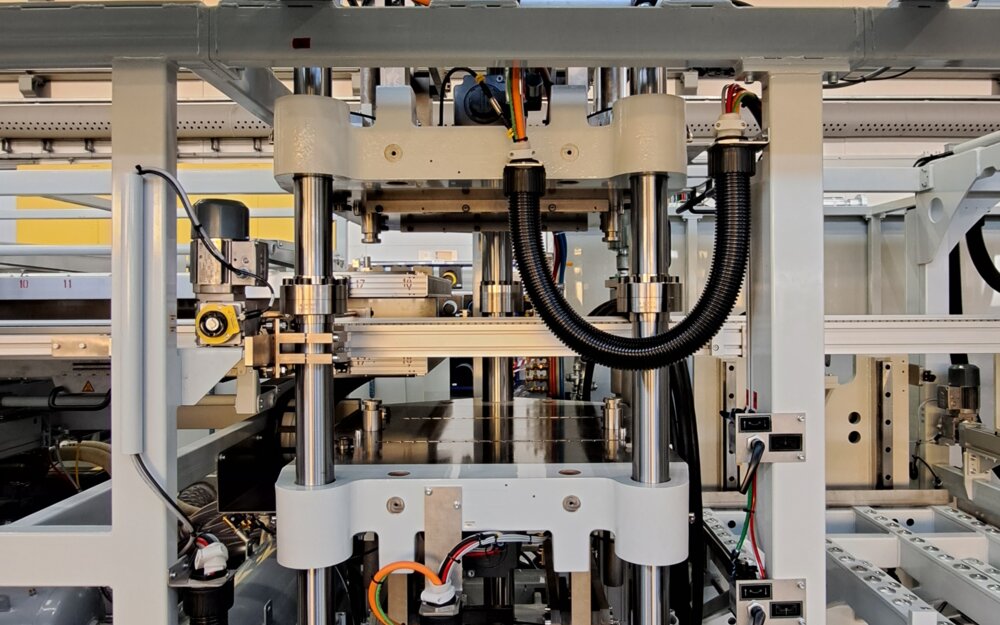

- Performance and process control: Servo motor drives for tables, plug assist, film transport & stacking pusher

- Production availability: Fast & easy tool change

- Efficient production: Repeatability & fast production readiness of heaters

- Easy operation & maintenance: HMI with large touch screen & proven operation, fully automatic lubrication

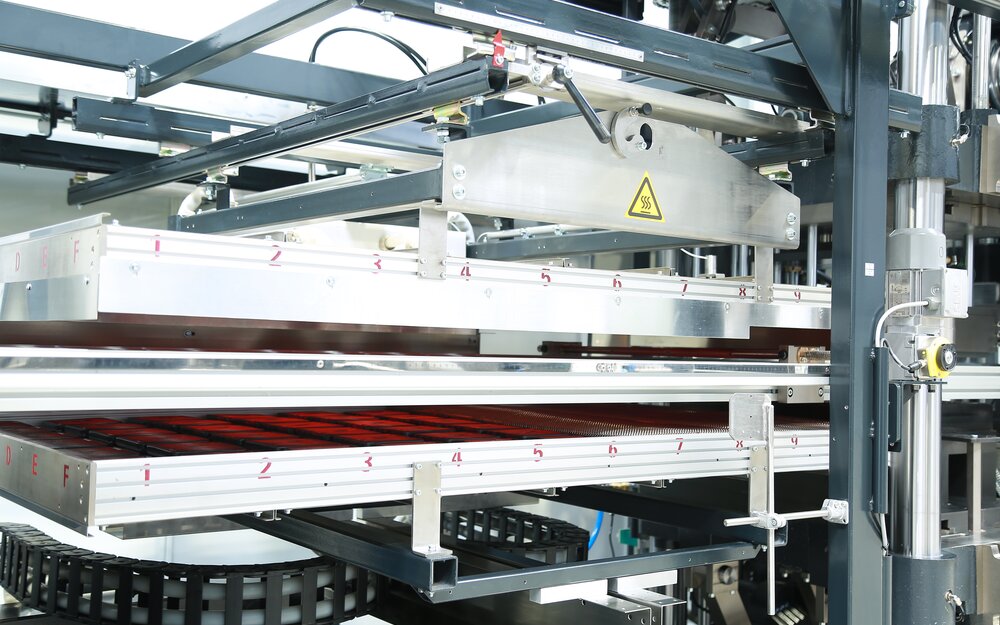

More productivity through reliable stacking:

Stacking is the first step towards automation. Safe and trouble-free stacking contributes to a significant reduction in labor costs. The SPEEDFORMER KMD 78 Smart modular system offers 4 different standard stacking solutions: Stacking up/down, Pick&Place stacking and tip stacking.

SPEEDFORMER KMD 78.2 Premium

Premium class for high productivity & performance

Improved in many areas, the KMD 78.2 Premium meets your production needs even better by enabling your customized configuration with proven up/down stacking, Pick&Place stacking as well as sophisticated tip stacking.

Your Kiefel benefits:

- More performance and process control: Servo motor drives for tables, plug assist, film transport & stacking pusher

- Higher machine availability: Fast & easy tool change

- Improved production efficiency for repeatability & fast production readiness of heaters

- Easier operation & maintenance: HMI with large touch screen & proven operation, fully automatic lubrication

Standard automation modules from Kiefel:

- Reduction of labor costs & improved ergonomics through innovative automation solutions.

- Available e.g. SPEEDPACKER

SPEEDFORMER KMD 78.2 Speed

Higher machine availability & more sustainable production

Benefit from the new generation KMD 78.2 Speed. The innovative machine series better meets your production needs by enabling tailor-made configuration with proven up & down stacking, pick & place stacking as well as sophisticated tip stacking.

Your Kiefel benefits:

- Performance and process control: Optimized forming, better cutting, smoother production

- Machine availability: Faster & ergonomic tool change, faster heater production readiness

- Efficiency & sustainability: More heating power - less consumption, intelligent lubrication system.

- Easy operation & maintenance: New HMI generation - intuitive operation, reduced input parameters, guided maintenance

Standard automation modules from Kiefel:

- Reduction of labor costs & improved ergonomics through innovative automation solutions.

- Available e.g. SPEEDPACKER, SPEEDPADDER

SPEEDFORMER KMD 78.2 Power

Easy use of already existing tools

Benefit from an easy installation of existing tools, like RDK tools, for example, with the KMD 78.2 Power according to the "plug & play" principle. No further adaptation is necessary here.

The innovative machine series also meets your production requirements through customized configuration with proven up stacking, pick & place stacking as well as sophisticated tip stacking.

Your Kiefel benefits:

- Performance and process control: Optimized forming, better cutting, smoother production

- Machine availability: Faster & ergonomic tool change, faster heater production readiness

- Efficiency & sustainability: More heating power - less consumption, intelligent lubrication system.

- Easy operation & maintenance: New HMI generation - intuitive operation, reduced input parameters, guided maintenance

Standard automation modules from Kiefel:

- Reduction of labor costs & improved ergonomics through innovative automation solutions.

- Available e.g. SPEEDPACKER, SPEEDPADDER

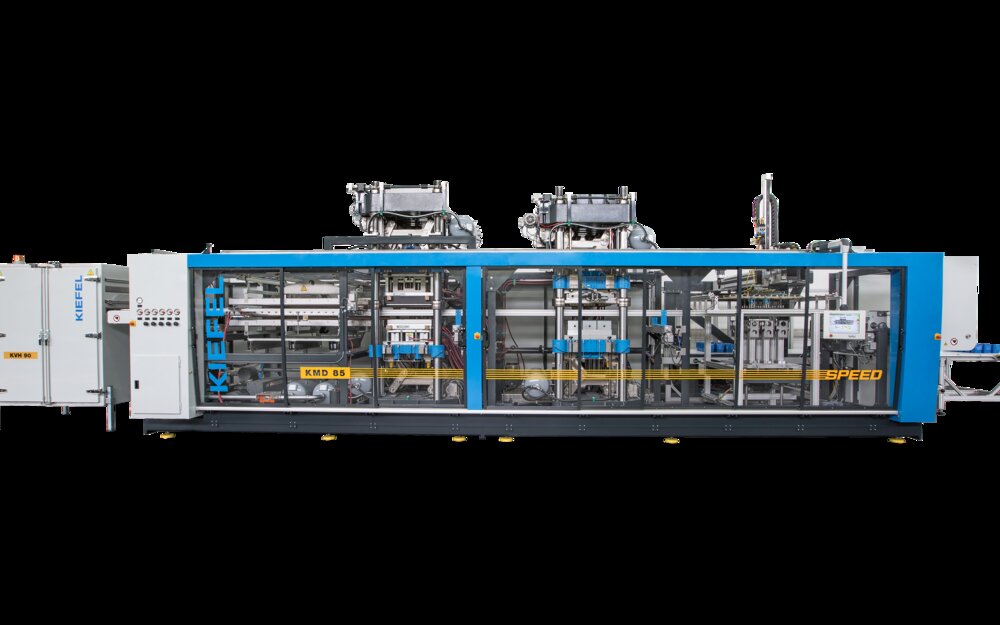

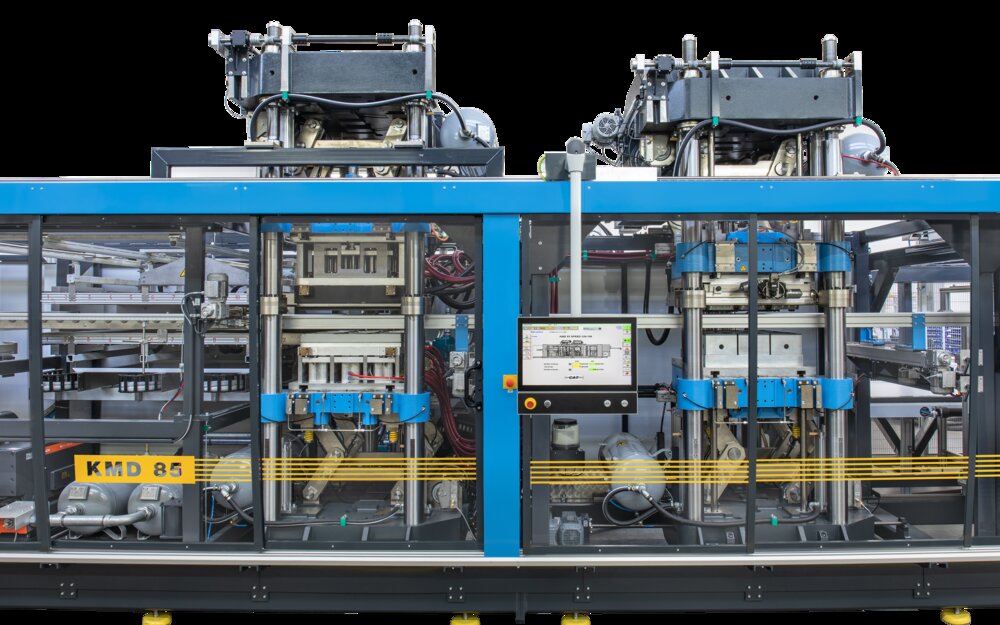

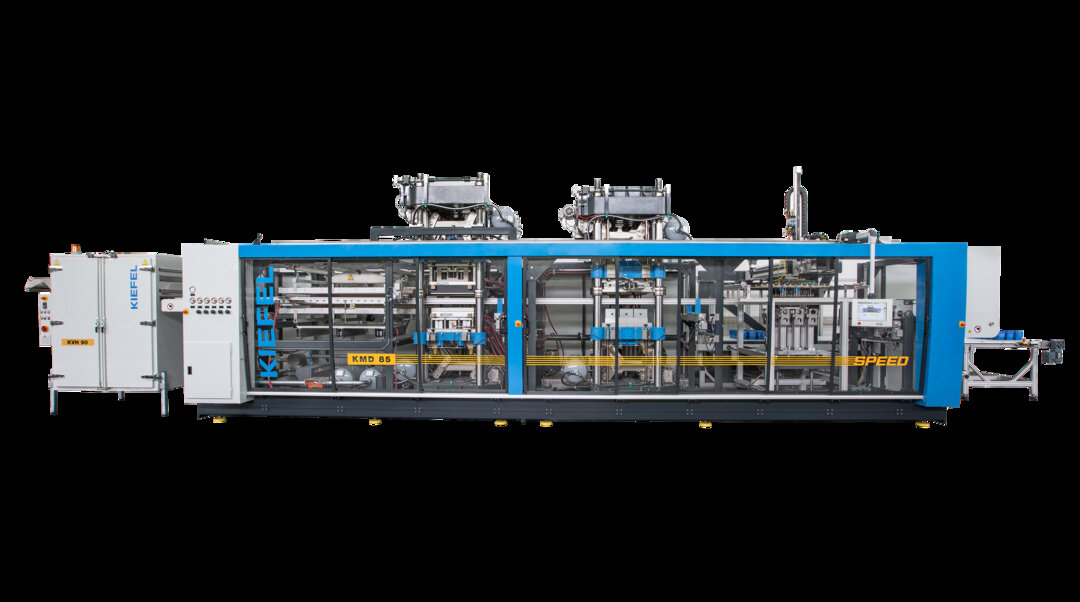

SPEEDFORMER KMD 85 Speed

Maximize production time & efficiency

The KMD 85 Speed combines customer and market needs like no other model.

The proven SPEEDFORMER model offers customized configuration with proven stacking solutions.

Your Kiefel benefits:

- Performance and process control: Servo motor drives for tables, plug assist, film transport & stacking pusher

- Machine availability: Faster & ergonomic tool change in one block

- Efficient production: Repeatability & fast production readiness of the heaters for stable forming conditions

- Easy operation: CAT control panel with intelligent software for quick & easy recipe creation

More productivity through reliable stacking:

Stacking is the first step towards automation. Safe and trouble-free stacking contributes to a significant reduction in labor costs. The SPEEDFORMER KMD 85 Speed modular system offers 3 different standard stacking solutions: Stacking up, Pick&Place stacking and tip stacking.

SPEEDFORMER KMD 90 Smart

German-Chinese success story with customer in focus

The KMD 90 Smart combines proven German technology with local manufacturing and technical support in China - a German-Chinese success story, 100% made by Kiefel. All engineering standards and quality processes are applied in China, guaranteeing the highest level of satisfaction.

Benefit from the use of simple and cost-effective tooling. As proven SPEEDFORMER model it perfectly meets your production requirements by enabling your customized configuration with proven down stacking.

The KMD 90 Smart is available for many countries - just contact us and find out which model best fits your requirements and get a quote.

Your Kiefel benefits:

- Performance and process control: Servo motor drives for tables, plug assist, film transport & stacking pusher

- Production availability: Fast & easy tool change in one block

- Efficient production: Repeatability & fast production readiness of heaters

- Easy operation & maintenance: HMI with large touch screen & proven operation, fully automatic lubrication

Optimized production with high cost-saving potential:

In addition to high performance and maximum energy savings, the modern KMD 90 also offers a fast tool change.

SPEEDFORMER KMD 90.1 Premium

Even more output when using existing tools

Benefit from easy use of existing tools, such as Sencorp 2500 series tools. As proven SPEEDFORMER model it perfectly meets your production requirements by enabling your customized configuration with proven down stacking as well as Pick&Place stacking.

Your Kiefel benefits:

- Performance and process control: Servo motor drives for tables, plug assist, film transport & stacking pusher

- Production availability: Fast & easy tool change in one block

- Efficient production: Repeatability & fast production readiness of heaters

- Easy operation & maintenance: HMI with large touch screen & proven operation, fully automatic lubrication

Optimized production with high cost-saving potential:

In addition to high performance and maximum energy savings, the modern KMD 90 also offers a fast tool change.

You can also benefit from easy installation of existing tools, such as Sencorp, on the KMD 90.1 Premium. This is done by means of a simple standard adapter.

Kiefel Driving Digital – KMI 2.0

Intuitive machine operation

Dive into the world of thermoforming 2.0 with the new machine interface generation KMI 2.0! The intuitive machine operation simplifies your thermoforming processes and supports you in many ways:

- Short training time

- Fast recipe optimization

- Fast error handling

- Guided maintenance system