Stacking & Automation Solutions

for tilting machines

We provide you with the right stacking & automation solutions for your SPEEDFORMER KTR such as the SPEEDSTACKER or the CUPPACKER.

Stacking

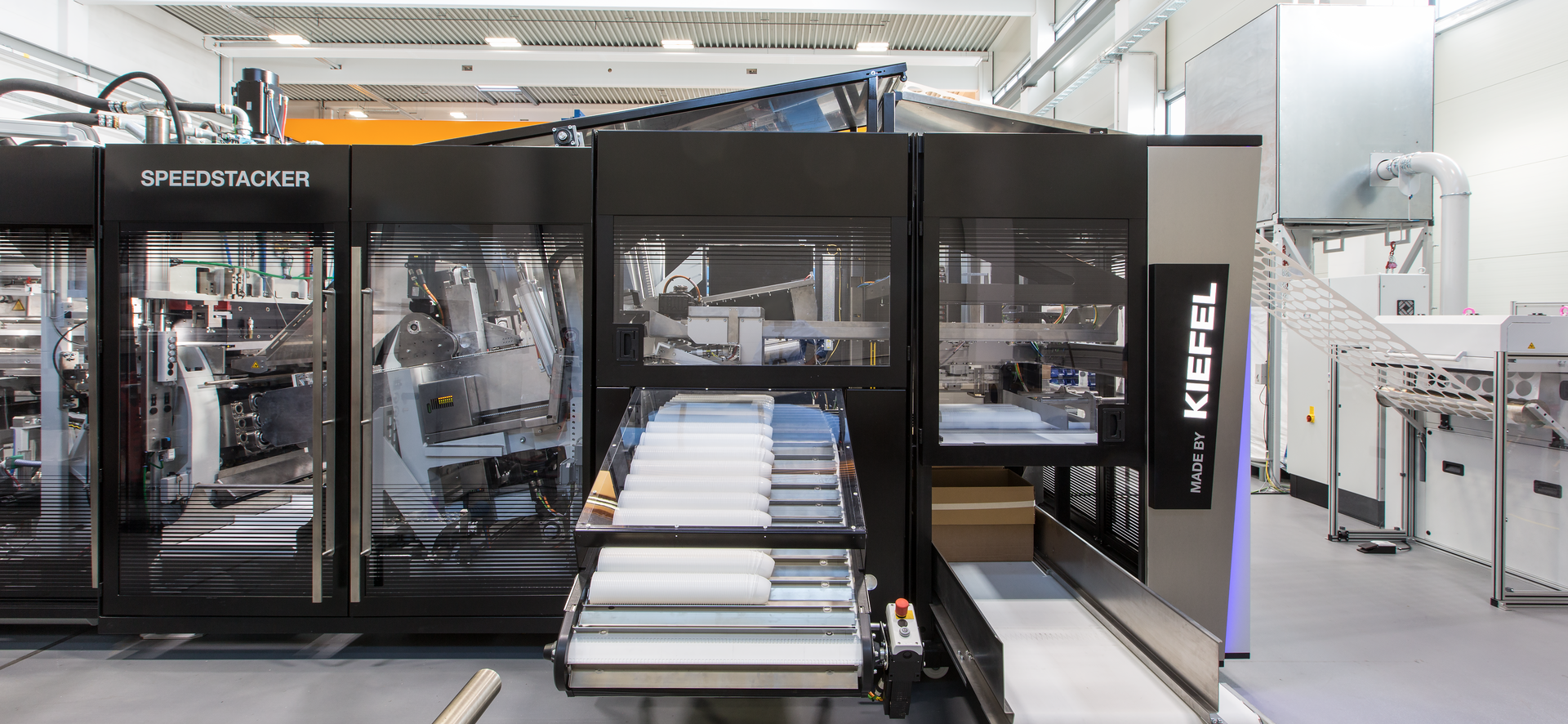

SPEEDSTACKER

The SPEEDSTACKER impresses with fully automatic stacking and packaging. It sets new standards in user-friendliness thanks to innovative technology - the SPEEDSTACKER brings the fastest ergonomic format change and guarantees absolute performance and top quality.

Benefits:

- Max. Speed & Performance for your production: Optimized movements and drives for the reliable transport of products - Packaging into boxes possible.

- Fast and easy change of format parts: Intelligent systems for efficient and ergonomic format change with improved accessibility to reduce changeover time

- Optimized product transfer: Processing of real-time signals for guaranteed maximum cycle times and smooth machine movements

Technical Highlights:

|

Max. cycles/stacks |

50 per min./25 per min. |

| Product dimensions | Ø 37 - 150 mm (non round products on request) |

| Product height | 25 – 200 mm |

| Stack length | 500 - 780 mm |

| Box dimensions | min. 500 x 340 x 210 mm (hxwxd) max. 800 x 800 x 600 mm (hxwxd) |

| Min. stacking area | 520 x 300 mm |

| Max. stacking area | 815 x 550 mm |

| Format changeover time | < 1 hour |

| Tool configuration | G / W / H |

SPEEDSTACKER COMPACT

The SPEEDSTACKER compact combines the advantages of the SPEEDSTACKER with an integrated carton filling solution. It features fully automatic carton filling and optional return conveyor for filled cartons on the operator side. With its modular design, it can be perfectly adapted to all requirements and pack up to 30 cup stacks per minute - hygienically and efficiently.

Download:

Automation

Vertisleever

The Vertisleever enables effective, simple and fast sleeving / packaging of cup stacks into sleeves. It can handle up to 20 stacks per minute at minimum footprint. Its flexible design makes it easy to adapt and maintain to various materials.

Benefits:

- Easy access to the film rolls at ergonomic height & simple exchange of the rolls

- Compact and flexible to adapt to new requirements

- Compliance with hygiene standards through automated sleeving

- Flexible use with new and existing machines also from other manufacturers

- Everything from a single source from the turnkey supplier

CUPPACKER - master of horizontal packing

Thanks to its modular design, the Kiefel CUPPACKER (KCP) adapts perfectly to all requirements and packs up to 30 cup stacks per minute - hygienically and efficiently.

At the same time, the KCP is so versatile that it is not only used in thermoforming lines, but can also be easily integrated into injection molding and printing lines.

Benefits:

- Highly customizable due to modular structur

- Fast product change due to less format parts

- Speed & Performance: Optimized servo drives and movements for reliable transfer of products

- Flexible & sophisticated design: Various packing patterns and flexibility on different carton formats

- Hygienic & ergonomic production: No risk of product contamination and support of healthy work posture

Technische Highlights:

| Stacks max. | up to 30 stacks/min |

| Article diameter | 68 - 150 mm |

| Stack length | 430 - 780 mm |

| Box dimensions | Min. 450 x 340 x 300 mm (lxwxh) Max. 800 x 600 x 600 mm (lxwxh) |

Kiefel Driving Digital – KMI 2.0

Intuitive machine operation

Dive into the world of thermoforming 2.0 with the new machine interface generation KMI 2.0! The intuitive machine operation simplifies your thermoforming processes and supports you in many ways:

- short training time

- fast recipe optimization

- fast error handling

- guided maintenance system