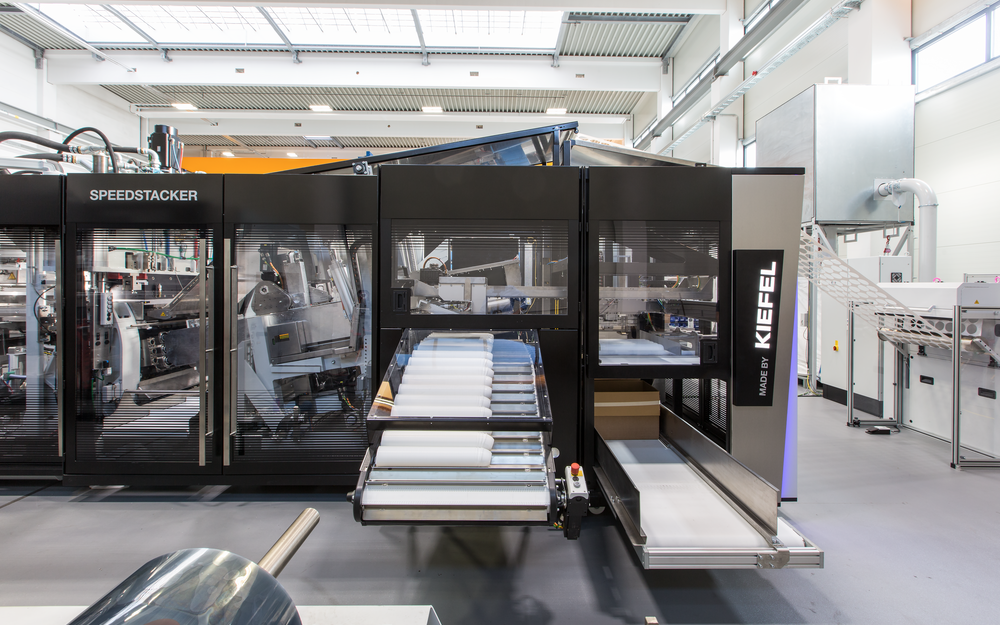

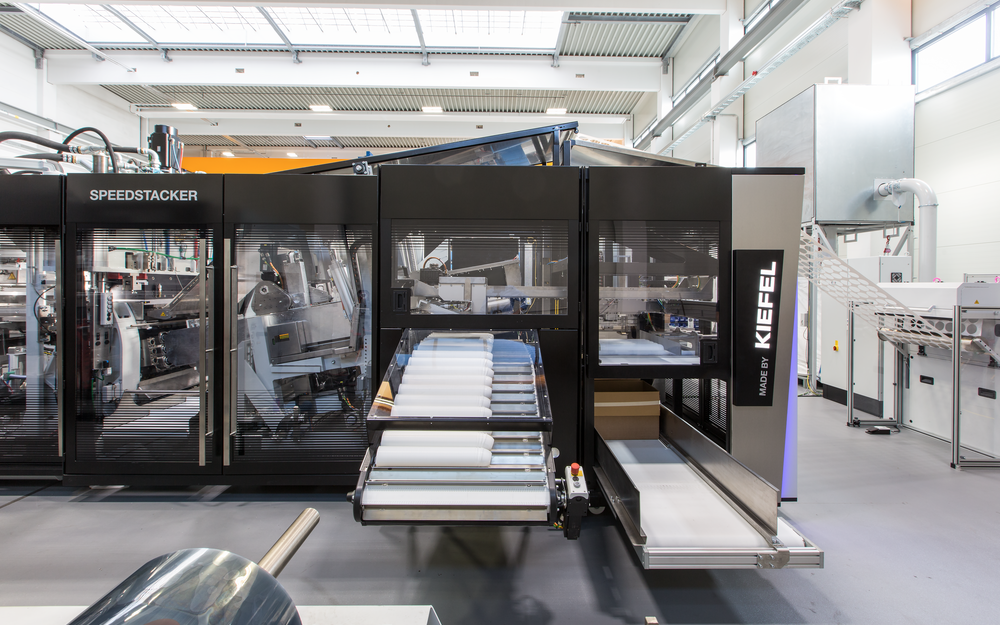

SPEEDFORMER KTR

Thermoform machines for high-end cup quality

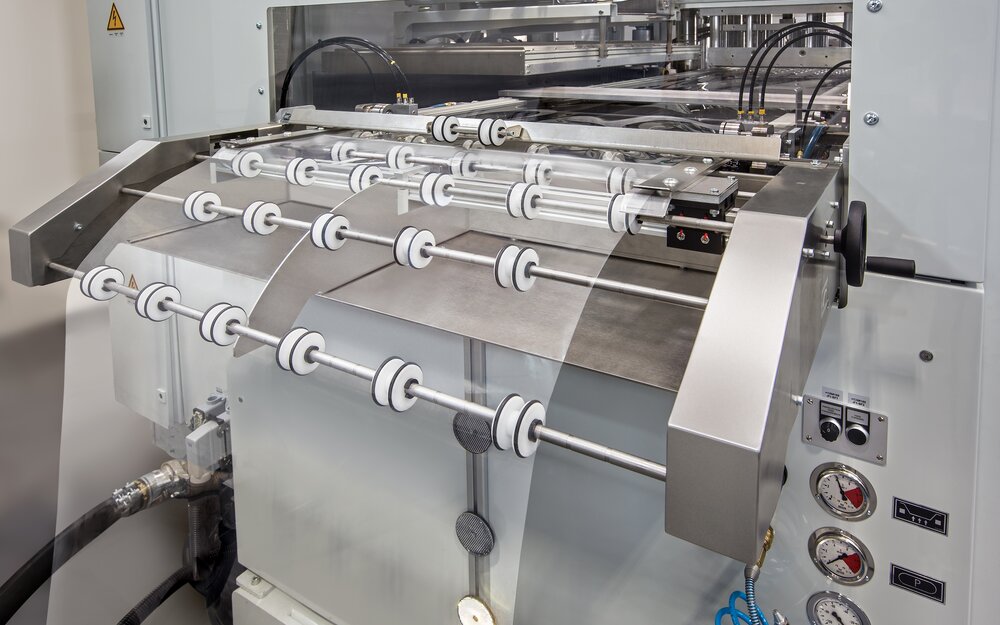

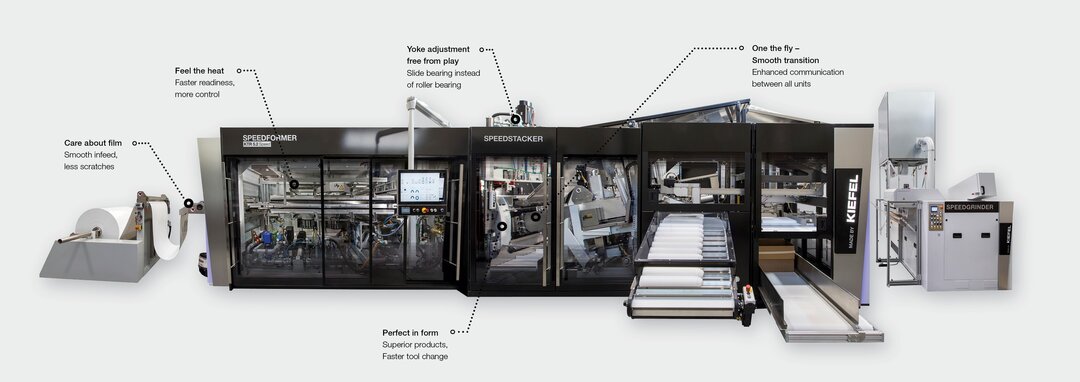

Due to the optimized forming area, space can be used for larger tools with more cavities which might increase your output.

Molding area and punching force are the decisive factors in maximizing performance. Flexibility is guaranteed when it comes to KTR systems: no matter if tools are supplied by Kiefel Packaging or your preferred tool designer.

The SPEEDFORMER KTR Series enables you to mass production of high-end cups using various film materials with different film properties.

Explore the KTR 6.2 Speed

Why SPEEDFORMER KTR?

Top quality for a wide range of edge and shape geometries

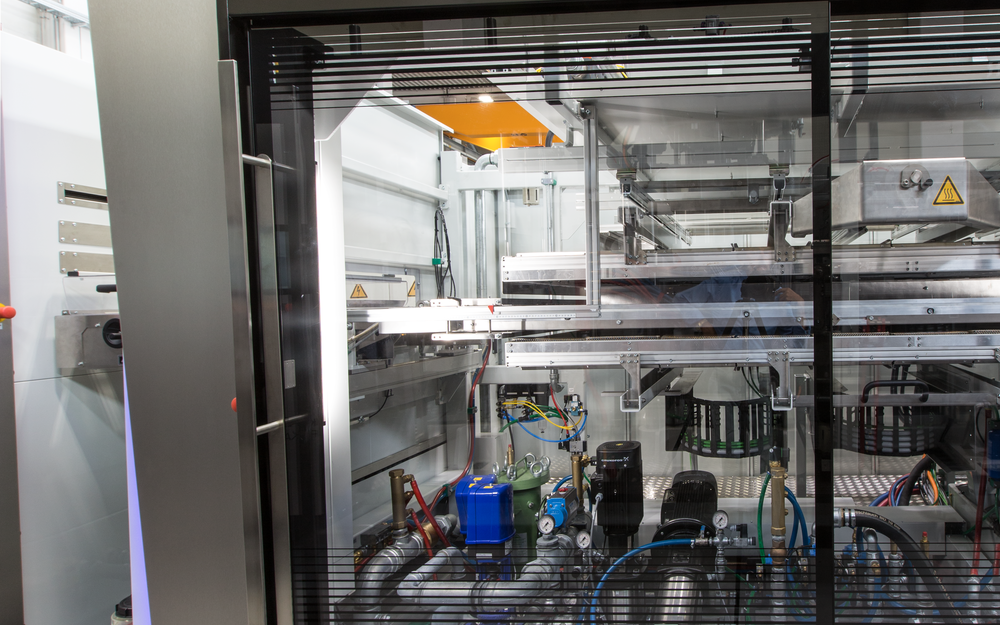

Increase in overall efficiency

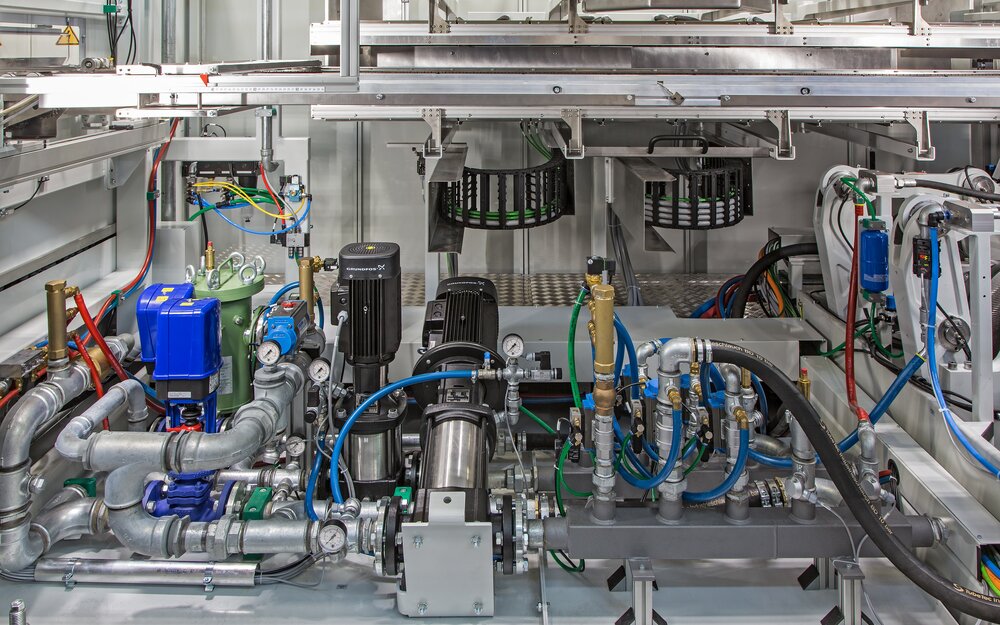

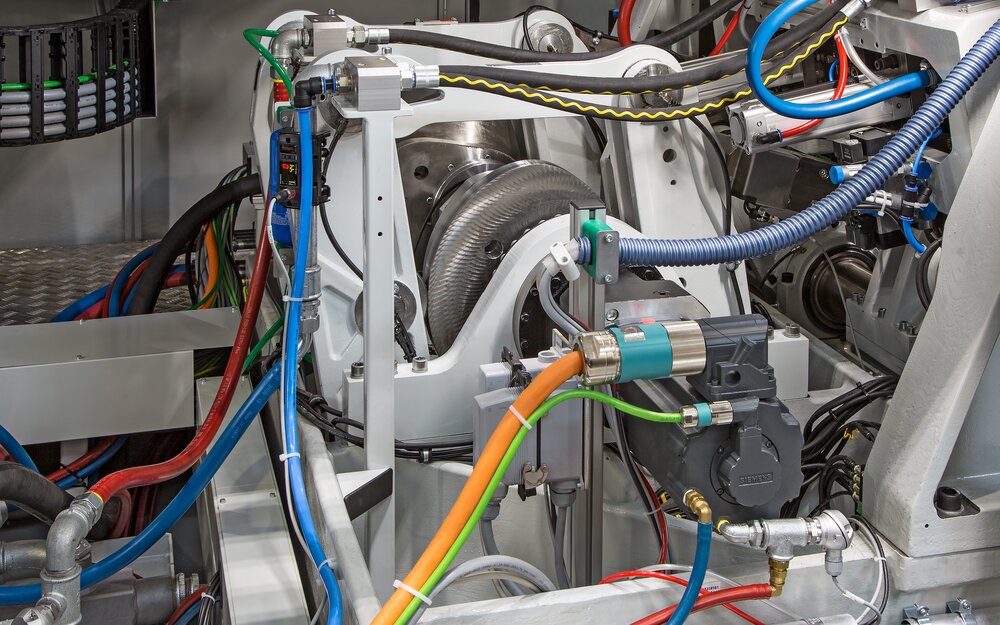

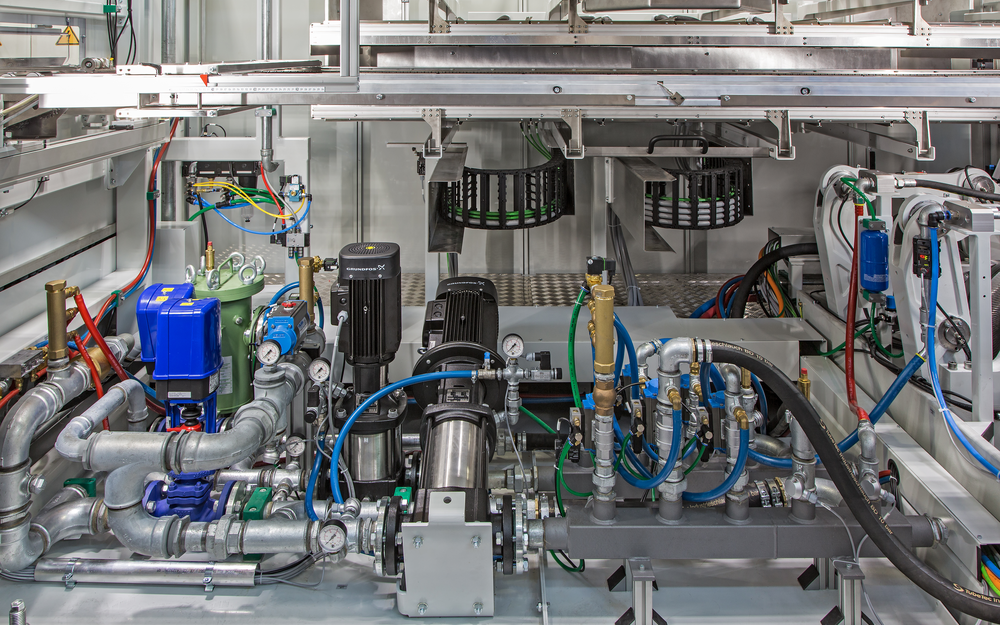

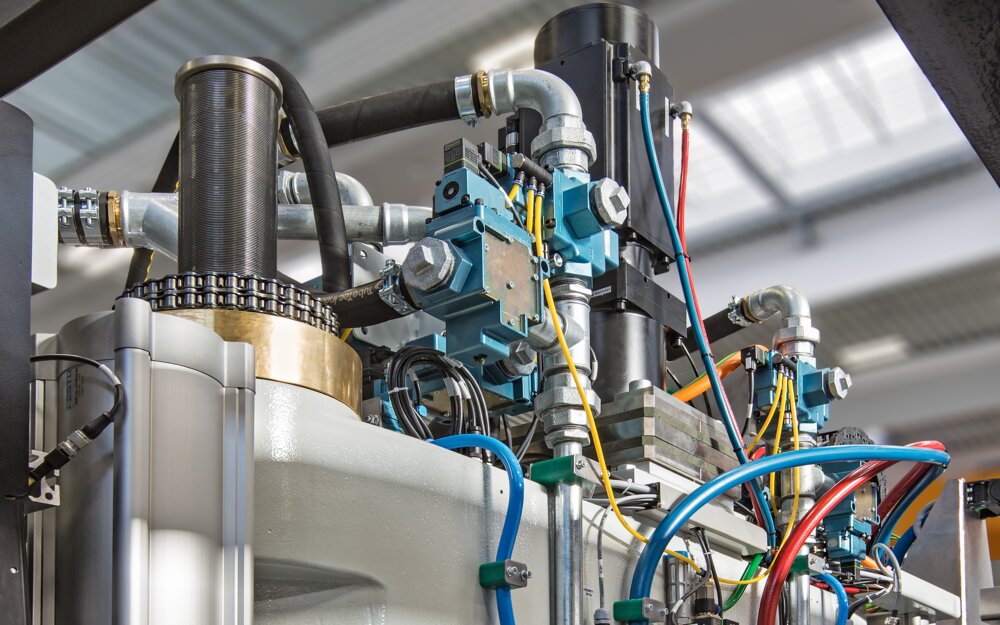

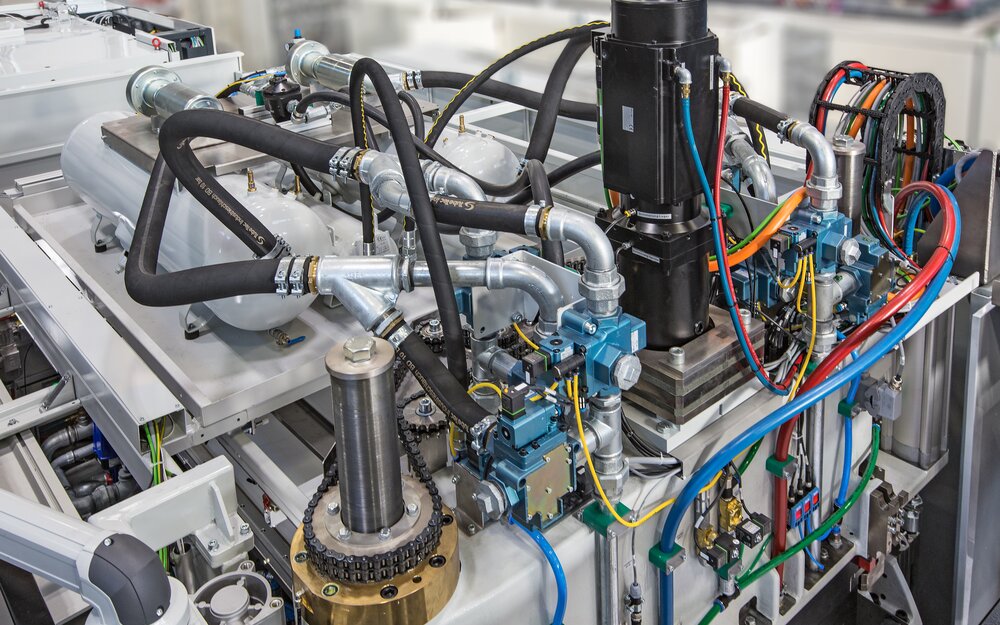

Process optimization & innovative technologies

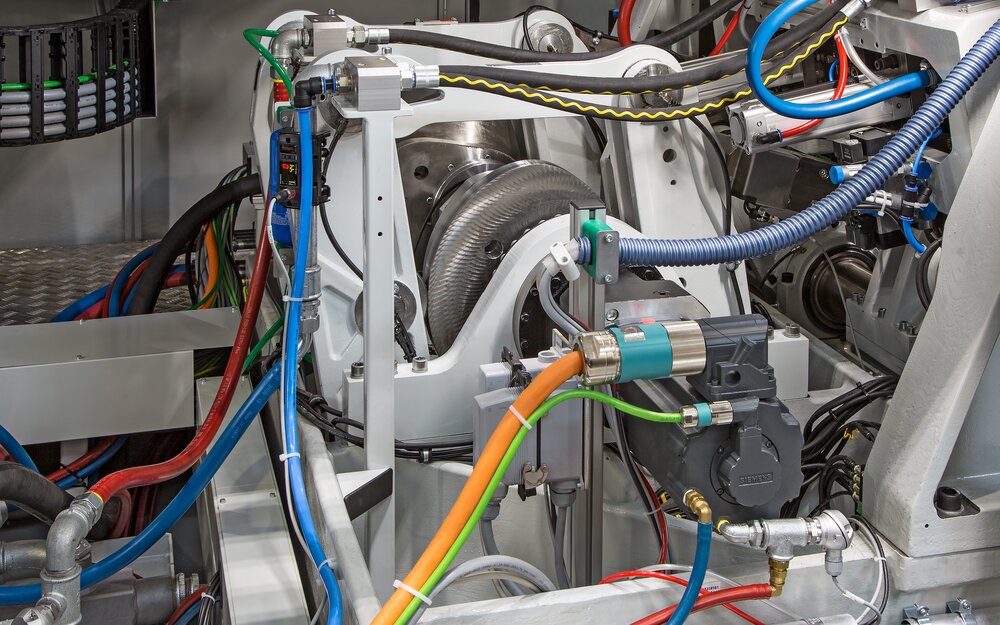

Faster production and maximum punching force with a low-vibration forming station

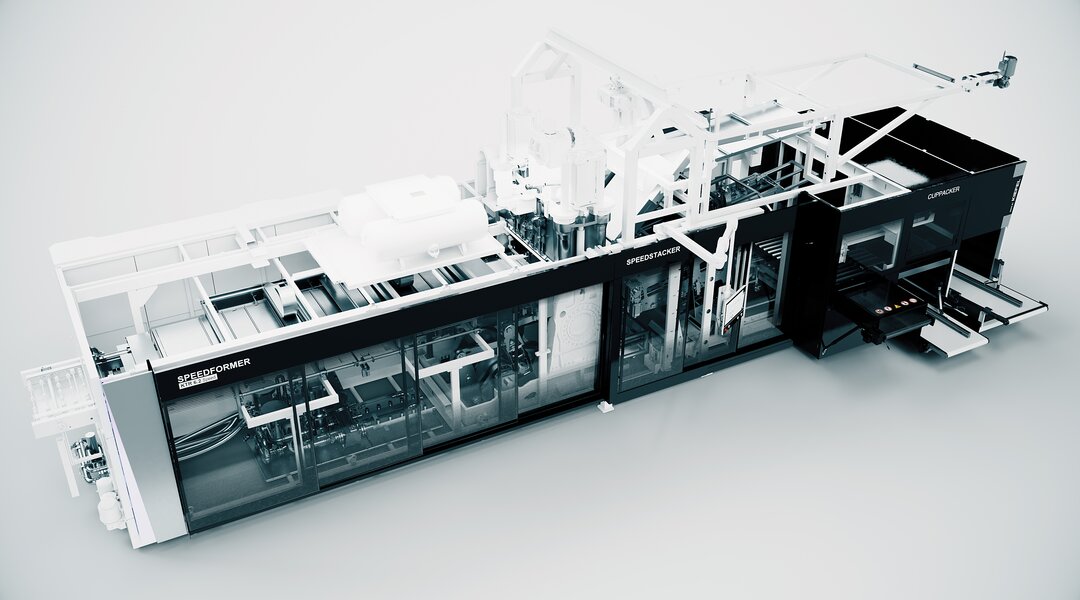

Versions of the SPEEDFORMER KTR

| KTR 5.2 Speed | KTR 6.2 Speed | |

|---|---|---|

| Max. forming area | 775 x 380 mm | 840 x 585 mm |

| Punching force | 400 kN | 900 kN |

| Cycle time | 50 cycles/min | 45 cycles/min |

| Max. height of formed part | 190 mm | 250 mm |

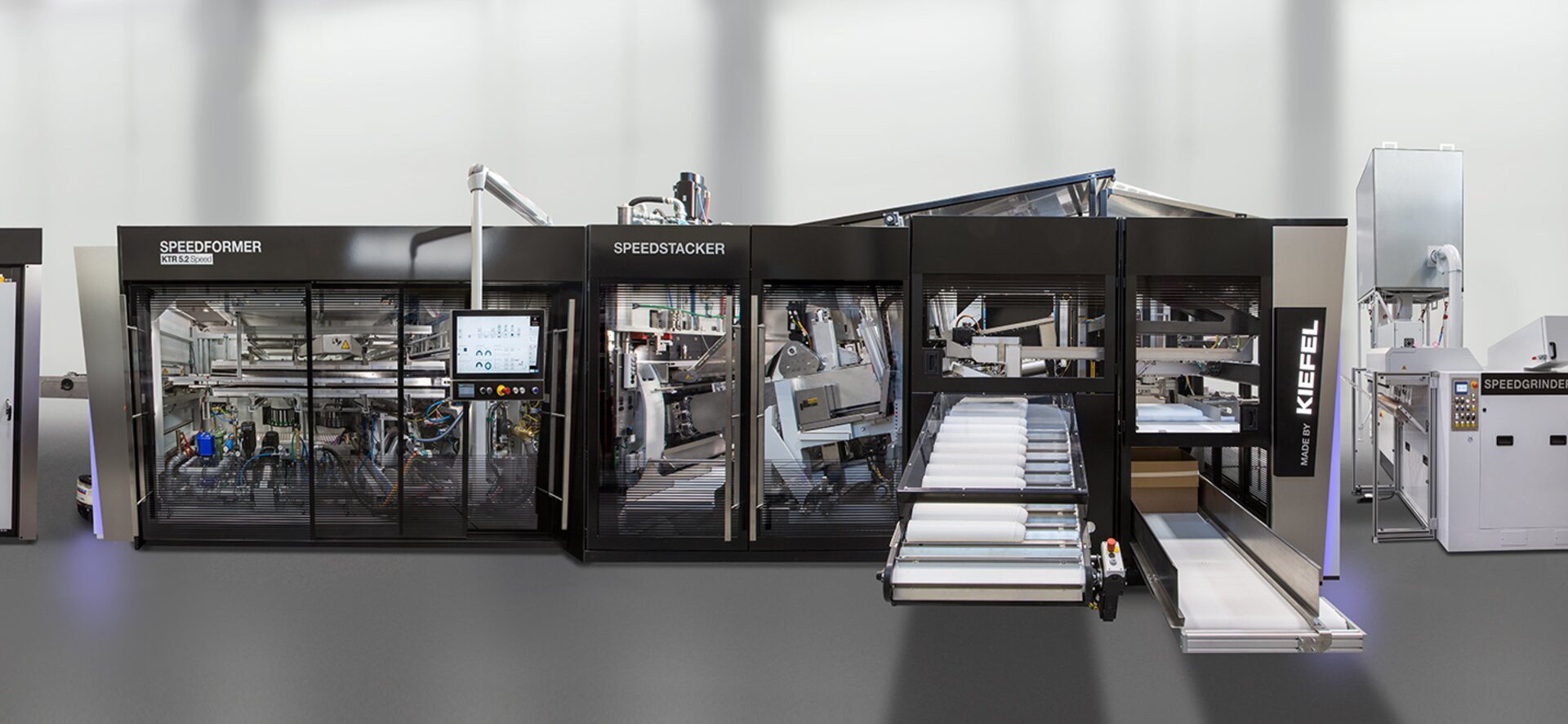

SPEEDFORMER KTR 5.2 SPEED

New generation, great impact

Benefit from the new generation KTR 5.2 Speed with increased production & maximum efficiency. With the innovative KTR 5.2 cup forming machine to the perfectly formed end product.

Your Kiefel benefits:

- Outstanding product quality due to enhanced film transport

- 10% energy savings due to evolved heating technology with new heating elements and insulation ensure

- Increased overall efficiency due to innovative, faster & easier tool change

- Process optimization – 25% faster forming air inlet, sensor-controlled cooling for ideal tool temperature

- Easy operation & maintenance: New HMI generation - intuitive operation, reduced input parameters, guided maintenance

Download:

SPEEDFORMER KTR 6.2 Speed

Pre-order now!

Up to 50% more output at the same footprint & quality

This advanced SPEEDFORMER KTR 6.2 cup forming machine sets the standard for efficiency, delivering over 50% higher output of high-quality cups and coffee capsules compared to other machine manufacturers.

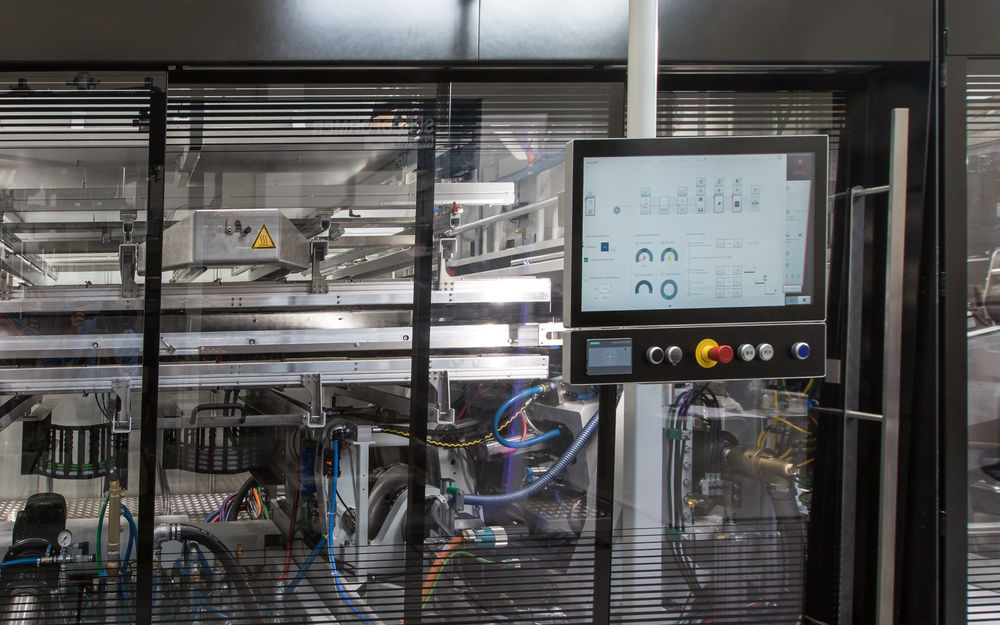

Kiefel Driving Digital – KMI 2.0

Intuitive machine operation

Dive into the world of thermoforming 2.0 with the new machine interface generation KMI 2.0! The intuitive machine operation simplifies your thermoforming processes and supports you in many ways:

- Short training time

- Fast recipe optimization

- Fast error handling

- Guided maintenance system